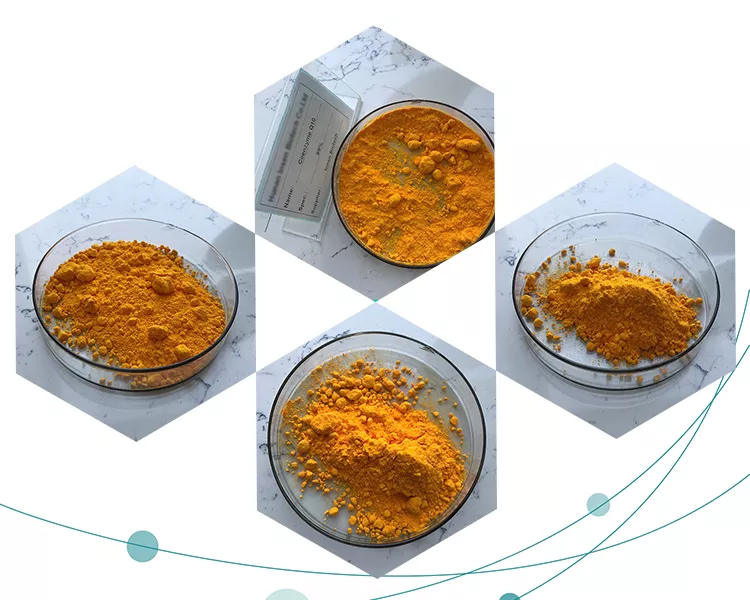

Coenzyme Q10 (CoQ10), also known as ubiquinone, is commonly produced through various methods, including microbial fermentation, chemical synthesis, and plant extraction. Each method has its advantages and limitations in terms of cost, efficiency, and purity. Here’s a closer look at the main production methods:

1. Microbial Fermentation

- Microorganisms such as Agrobacterium tumefaciens or Yeast (e.g., Rhodobacter sphaeroides) are commonly used.

- Process: Fermentation conditions are optimized for high Coenzyme Q10 yield. The microbes produce Coenzyme Q10 as a secondary metabolite, which is then extracted and purified.

- Advantages: Produces a bio-identical form of Coenzyme Q10 (more easily absorbed), environmentally friendly, and scalable for industrial production.

- Limitations: Complex downstream processing and potential variability in yield due to microbial activity.

2. Chemical Synthesis

- Chemical reactions are used to create Coenzyme Q10 from petrochemical-derived precursors.

- Process: Multi-step organic synthesis often involves using intermediates like isoprene units, which are assembled to form the Coenzyme Q10 molecule.

- Advantages: Allows precise control over production yield, typically faster than microbial methods.

- Limitations: Costly, may require toxic solvents, and the resulting Coenzyme Q10 may differ slightly in structure (e.g., trans-isomer formation) compared to naturally occurring Coenzyme Q10, affecting bioavailability.

3. Plant Extraction

- Sources like parsley and perilla have high levels of Coenzyme Q10.

- Process: Plants are harvested and extracted to isolate Coenzyme Q10, which is then purified.

- Advantages: Natural source, potentially bio-identical, and an option for “natural” product markets.

- Limitations: Low Coenzyme Q10 content in plants makes it difficult to scale, leading to high production costs.

4. Biotechnological and Genetic Engineering Methods (Emerging)

- Genetically modified organisms (e.g., engineered strains of bacteria or yeast) are developed to produce higher Coenzyme Q10 levels.

- Process: Genetic modification enhances metabolic pathways in microorganisms, boosting Coenzyme Q10 production.

- Advantages: Can achieve high yields and cost-effectiveness, minimal environmental impact.

- Limitations: Regulatory challenges and public concerns over GMOs in some markets.

Summary of Commercial Usage

For large-scale production, microbial fermentation and biotechnological engineering are the most common due to their cost-effectiveness, scalability, and ability to produce a bio-identical Coenzyme Q10 form suitable for dietary supplements and pharmaceuticals.