Ivermectin is a drug derived from avermectins, a group of compounds produced by the bacterium Streptomyces avermitilis. It is widely used as an antiparasitic agent in both humans and animals. Below is an overview of its preparation process:

1. Cultivation of Streptomyces avermitilis

- Isolation: The bacterium Streptomyces avermitilis is grown in a controlled fermentation environment.

- Fermentation medium: The growth medium typically contains nutrients like glucose, soybean meal, and essential salts to support microbial growth and metabolite production.

- Optimal conditions: The fermentation is carried out under specific conditions of pH, temperature (25–28°C), and aeration to maximize the production of avermectins.

2. Extraction of Avermectins

- After fermentation, the culture broth contains the avermectins, which are extracted using organic solvents such as ethyl acetate or methanol.

- The solvents are used to separate the compounds from the microbial biomass and the fermentation medium.

3. Purification of Avermectins

The crude extract is subjected to:

- Liquid-liquid extraction to separate impurities.

- Chromatographic techniques, such as silica gel or reverse-phase chromatography, to isolate specific avermectin derivatives.

4. Chemical Modification to Ivermectin

- The purified avermectins (specifically avermectin B1a and B1b) are chemically modified to produce ivermectin.

- Hydrogenation: Selective hydrogenation of specific functional groups (e.g., double bonds) creates ivermectin from the parent compounds.

- Proportioning: The final product contains about 80% of ivermectin B1a and 20% of ivermectin B1b.

5. Formulation

The synthesized ivermectin is formulated into different dosage forms depending on its intended use:

- Tablets for oral administration (humans).

- Injections for veterinary use.

- Topical formulations like creams or lotions for external use.

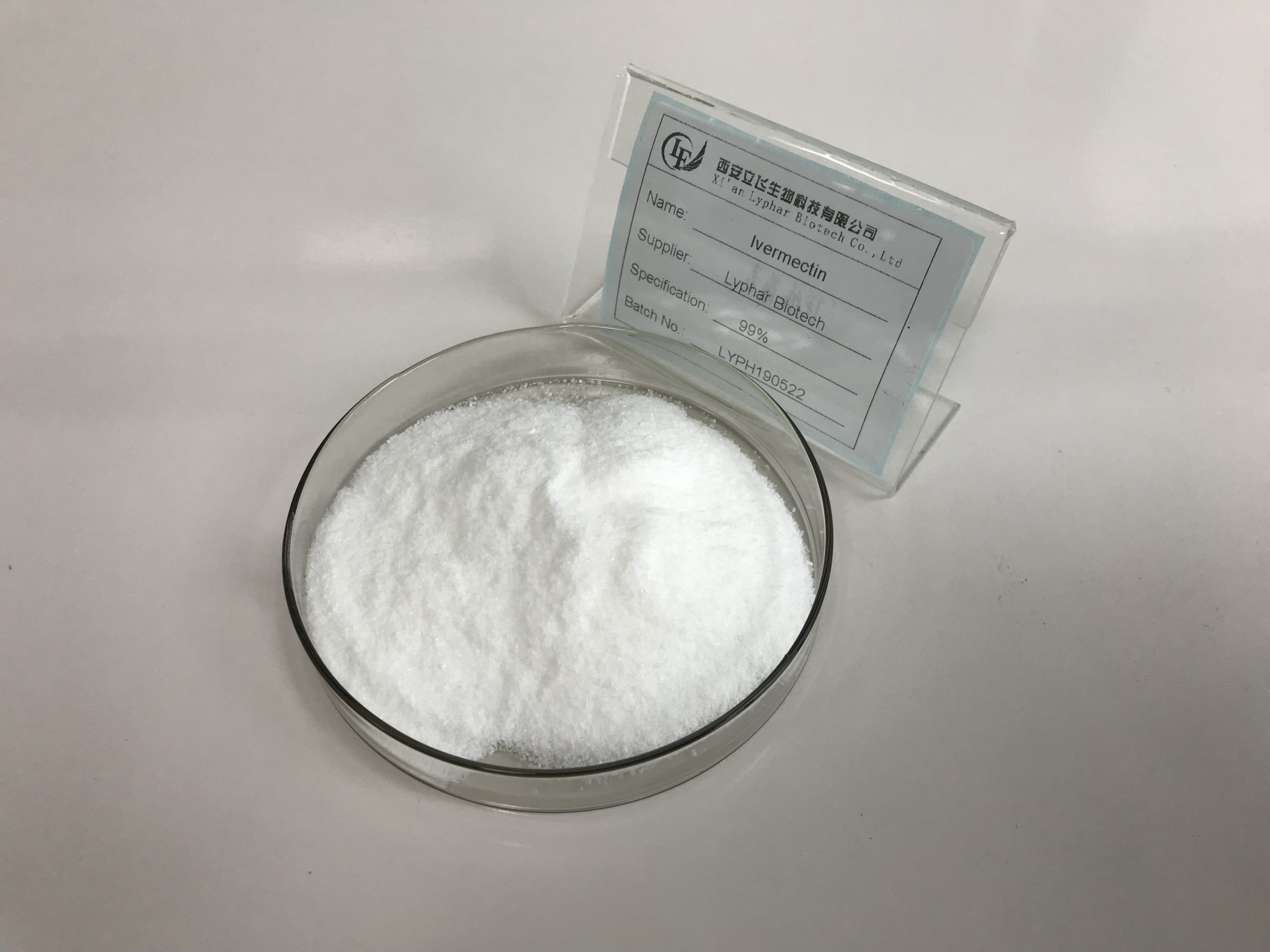

6. Quality Control

Rigorous testing ensures the product meets standards for:

- Purity (high-performance liquid chromatography, HPLC).

- Potency (bioassays).

- Safety (toxicity studies).

Would you like detailed steps on any specific aspect of the process?