Production process of royal jelly powder involves several steps to ensure the transformation of raw royal jelly into a stable, high-quality powdered form. Below is an overview of the typical production process:

1. Collection of Raw Royal Jelly

- Royal jelly is harvested from queen bee cells in beehives. This involves carefully extracting the substance without harming the bees.

- The raw royal jelly is usually stored at low temperatures to prevent degradation.

2. Preliminary Filtration and Purification

- The harvested royal jelly is filtered to remove impurities such as wax, pollen, or bee residues.

- It is further purified to meet safety and quality standards.

3. Quality Testing

- Samples of the raw royal jelly powder are tested for contaminants, microbiological safety, and the presence of key active compounds like 10-hydroxy-2-decenoic acid (10-HDA).

4. Pasteurization

- The royal jelly undergoes mild heat treatment (pasteurization) to eliminate harmful microbes while preserving its bioactive compounds.

5. Concentration

- Excess water is removed to concentrate the royal jelly, reducing its volume and preparing it for the drying process.

6. Spray Drying or Freeze Drying

- Spray Drying: The concentrated royal jelly powder is converted into fine droplets and rapidly dried using hot air. This method is fast but may affect heat-sensitive components.

- Freeze Drying (Lyophilization): The concentrated royal jelly is frozen and subjected to a vacuum to sublimate the ice directly into vapor, preserving more bioactive compounds and nutrients.

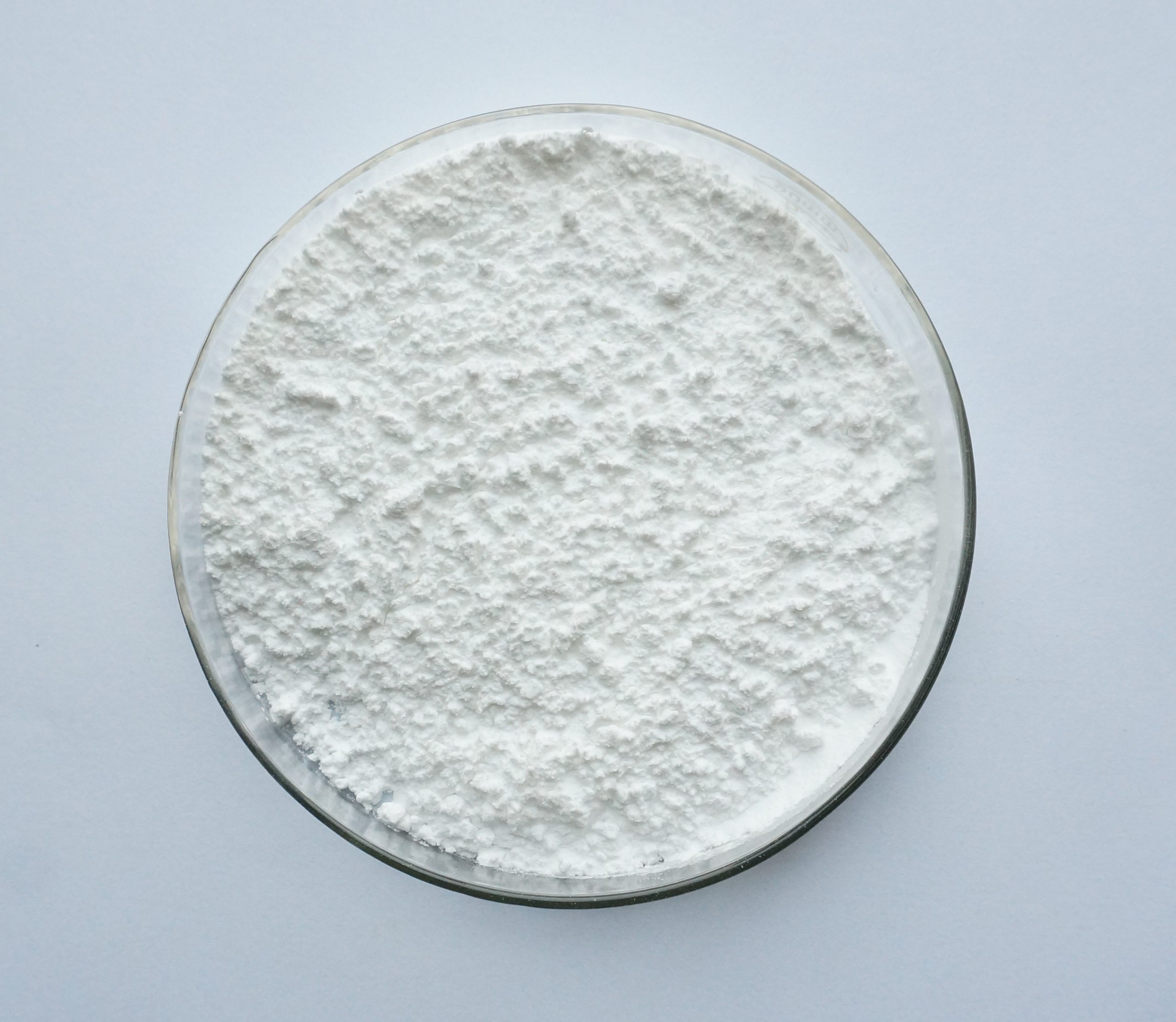

7. Powder Formation

- The dried royal jelly is ground into a fine powder.

- Anti-caking agents (such as maltodextrin) are sometimes added to prevent clumping and improve shelf life.

8. Packaging

- The royal jelly powder is sealed in air-tight, moisture-proof, and light-resistant packaging to maintain its quality.

- It is labeled and prepared for distribution or encapsulation into supplements.

9. Final Quality Check

- The finished product undergoes another round of quality assurance testing for purity, potency, and compliance with regulatory standards.

Key Considerations in Production

- Temperature Control: Maintaining low temperatures throughout the process is critical to preserving the bioactive properties of royal jelly powder.

- Hygiene and Safety: The production environment must adhere to strict sanitary standards to avoid contamination.

- Quality Standards: Compliance with Good Manufacturing Practices (GMP) ensures the reliability of the product.

Would you like further details about any specific step or the equipment used?