As of my last knowledge update in September 2021, isosorbide dimethyl ether (IDME) is a compound that has shown potential for use as a renewable and environmentally friendly solvent in various industrial applications. Isosorbide is a biobased diol derived from agricultural feedstocks like corn and is often used as a starting material for the synthesis of various derivatives, including isosorbide dimethyl ether.

Some potential uses and applications of isosorbide dimethyl ether include:

Green Solvent: isosorbide dimethyl ether has been investigated as a green solvent in industries such as coatings, paints, and adhesives. Its low volatility, high boiling point, and ability to dissolve a wide range of organic compounds make it an attractive alternative to conventional solvents that are often derived from petrochemical sources and can be harmful to the environment.

Polymer Production: Isosorbide dimethyl ether can be used as a co-monomer or a reactive diluent in the production of polymers. It can improve the properties of polymers by enhancing their biodegradability, thermal stability, and mechanical strength. It has been studied as an additive in bioplastics to improve their performance and reduce their environmental impact.

Pharmaceuticals: isosorbide dimethyl ether and its derivatives have been explored in pharmaceutical applications. They can be used as solvents for drug formulation and as intermediates in the synthesis of certain pharmaceutical compounds.

Chemical Synthesis: Isosorbide dimethyl ether can be utilized in various chemical reactions as a solvent, reactant, or reaction medium. Its unique properties can sometimes lead to increased reaction rates or selectivity in certain reactions.

Fuel Additive: There have been studies exploring the potential of using isosorbide dimethyl ether as a fuel additive to improve the combustion properties of biodiesel and reduce emissions. Its high oxygen content can enhance the combustion efficiency of biodiesel blends.

Personal Care Products: IDME’s solvating abilities and biobased nature have led to its investigation as a potential ingredient in personal care products such as cosmetics, lotions, and creams.

It’s important to note that the research and development landscape is constantly evolving, and new applications for compounds like isosorbide dimethyl ether may have emerged since my last update. If you’re looking for the most up-to-date and accurate information about the uses and applications of IDME, I recommend consulting recent scientific literature, industry reports, and experts in the field of green chemistry and sustainable materials.

Quality and production of Isosorbide Dimethyl Ether

Isosorbide Dimethyl Ether (ISDME) is a chemical compound that is derived from isosorbide, which itself is obtained from renewable sources like corn or sugarcane. ISDME is primarily used as a green solvent and can replace conventional solvents in various industrial processes, providing environmental and safety advantages. It has low volatility, low toxicity, and is biodegradable, making it an attractive option for sustainable production.

The quality and production of Isosorbide Dimethyl Ether involve several steps:

Isosorbide Production: Isosorbide is typically obtained through the dehydration of D-sorbitol, which can be derived from biomass sources like corn stover, wheat straw, or sugarcane bagasse. This involves a series of chemical reactions to convert the biomass feedstock into isosorbide.

Etherification Reaction: The production of Isosorbide Dimethyl Ether involves the etherification of isosorbide with methanol. This reaction usually requires a catalyst and controlled conditions to promote the formation of ISDME while minimizing unwanted byproducts.

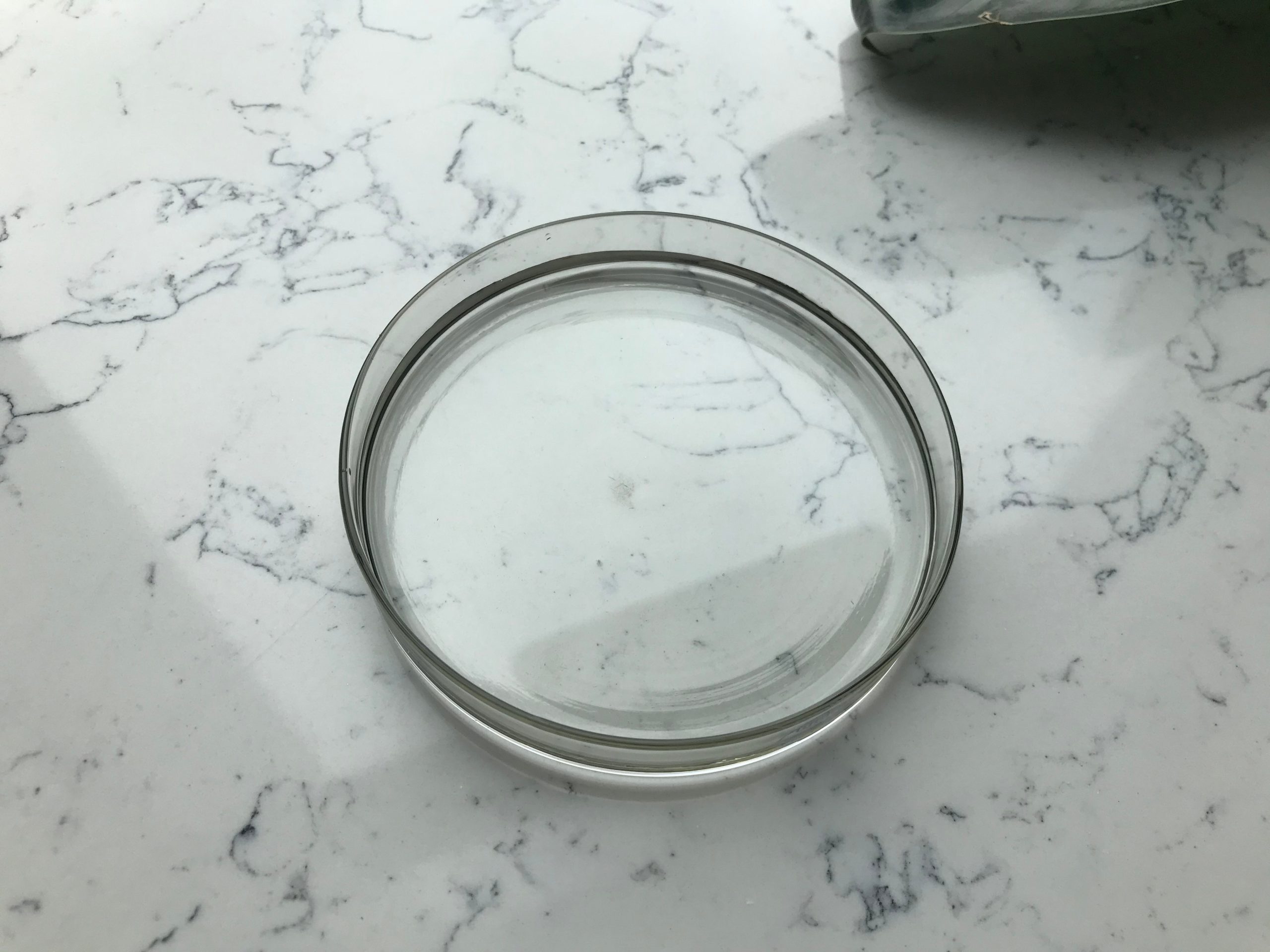

Purification and Separation: After the reaction, the mixture needs to be purified to isolate the desired Isosorbide Dimethyl Ether. This purification process may involve distillation, crystallization, or other separation techniques to remove impurities and excess reactants.

Quality Control: Ensuring the quality of ISDME is crucial for its intended applications. Quality control measures involve analyzing the purity of the compound, checking for the presence of impurities, and confirming that it meets the required specifications for its intended use.

Safety and Environmental Considerations: One of the main advantages of using Isosorbide Dimethyl Ether is its lower environmental impact compared to traditional solvents. The production process should be designed to minimize waste generation, energy consumption, and emissions. Additionally, the safety of workers involved in the production process should be a priority.

Scaling up Production: Developing a scalable production process is essential to meet industrial demand. This involves optimizing reaction conditions, scaling up equipment, and ensuring consistent product quality at larger production scales.

Regulatory Compliance: The production and use of chemical compounds like ISDME are subject to regulatory requirements that vary by region. Manufacturers must ensure that their production processes and products comply with relevant regulations and safety standards.

Overall, the quality and production of Isosorbide Dimethyl Ether require careful attention to detail in each step of the process, from obtaining the starting materials to synthesizing the compound and ensuring its purity and sustainability. It’s important for manufacturers to invest in research and development to improve production efficiency, reduce costs, and enhance the compound’s suitability for various applications.