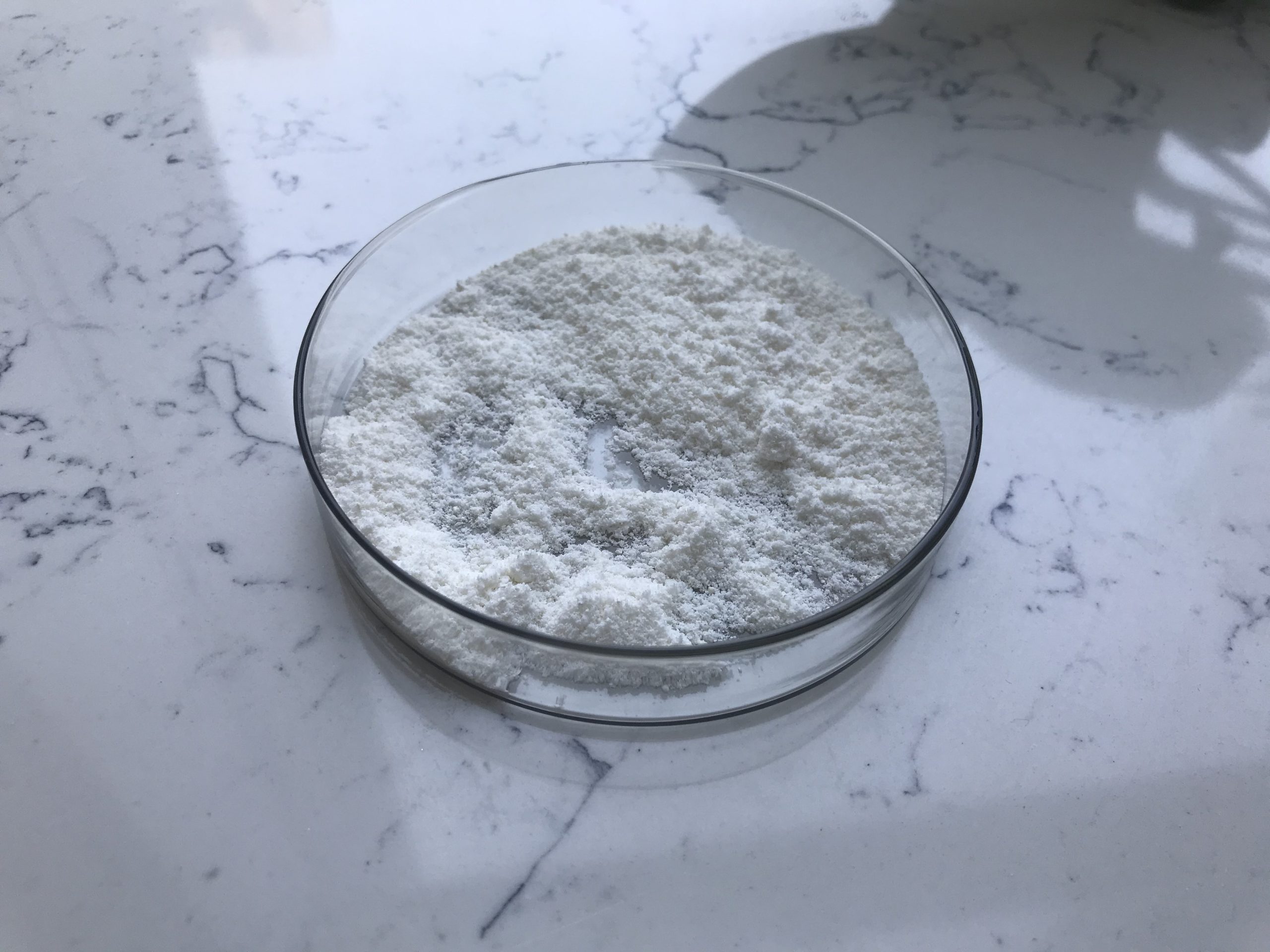

Nicotinamide Riboside (NR) is a form of vitamin B3 that has gained attention for its potential health benefits, particularly in the context of aging and cellular health. Here are the typical materials and methods used in the research and production of Nicotinamide Riboside:

Materials of Nicotinamide Riboside:

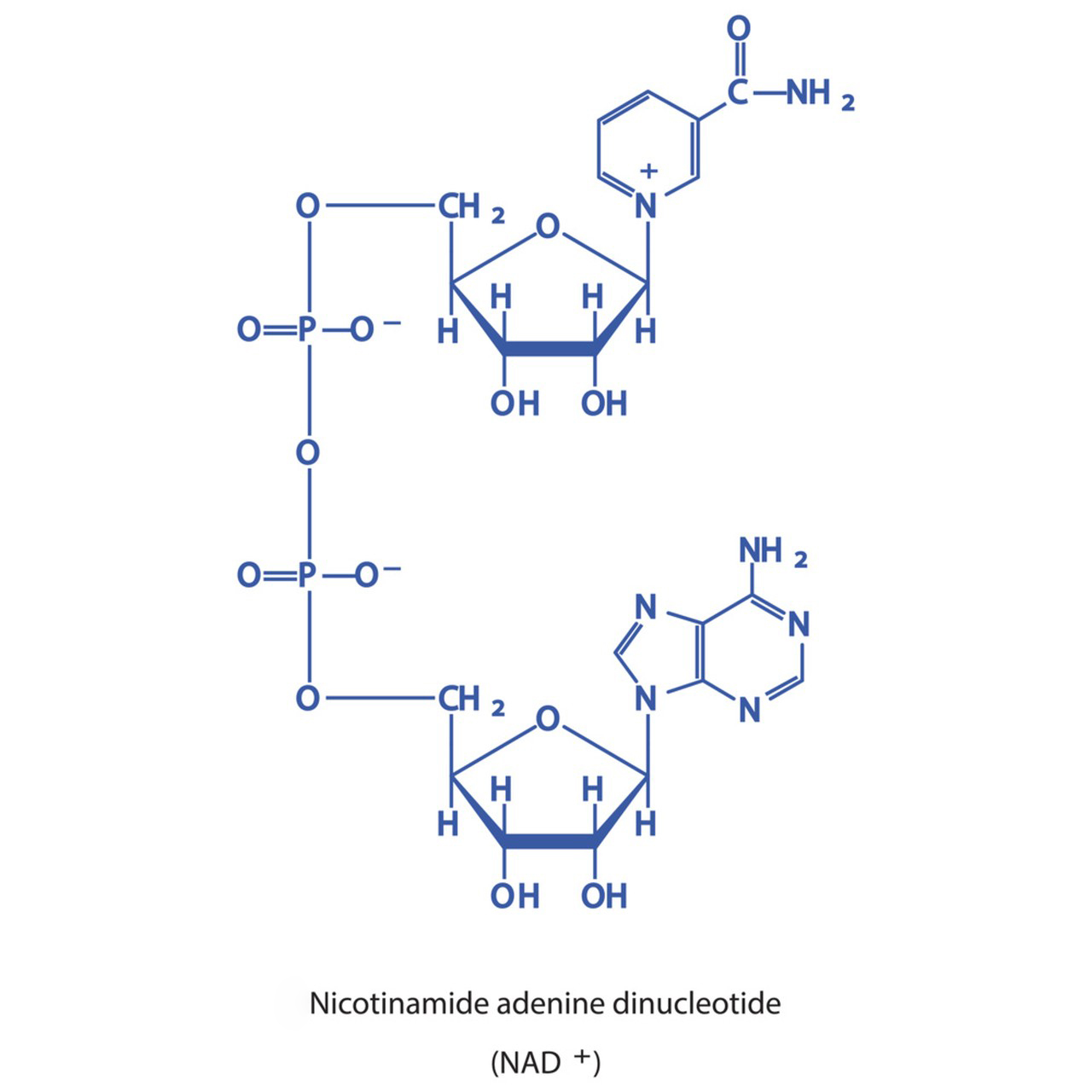

- Nicotinamide Mononucleotide (NMN): NMN is a precursor to NR and is often used as a starting material for NR synthesis.

- Chemicals and Reagents: Various chemicals and reagents are required for the synthesis and purification of NR. This includes solvents, catalysts, and other chemicals.

- Laboratory Equipment: Standard laboratory equipment such as glassware, reaction vessels, chromatography columns, and analytical instruments are used in the production and analysis of NR.

- Yeast or Bacterial Strains: Nicotinamide Riboside (NR) can be produced through fermentation using yeast or bacterial strains engineered to produce NR.

Methods of Nicotinamide Riboside:

- Chemical Synthesis: NR can be chemically synthesized from nicotinamide or NMN through various chemical reactions. The specific synthetic route can vary, but it often involves reactions like condensation, reduction, and purification steps.

- Fermentation: Nicotinamide Riboside (NR) can also be produced through fermentation processes using engineered yeast or bacterial strains. These microorganisms are designed to convert precursor molecules into NR. Fermentation typically involves the following steps:

- Microorganism Cultivation: The engineered yeast or bacteria are grown in a bioreactor under controlled conditions.

- Substrate Addition: The precursor molecule, such as NMN, is added to the bioreactor as a substrate.

- Fermentation: During fermentation, the microorganisms metabolize the substrate and produce NR as a byproduct.

- Purification: After fermentation, NR is typically separated and purified from the fermentation broth using various techniques like chromatography.

- Analysis and Quality Control: Nicotinamide Riboside (NR) produced through either chemical synthesis or fermentation must undergo rigorous analysis to ensure purity and quality. Analytical methods such as high-performance liquid chromatography (HPLC) are often used to quantify NR content and assess its purity.

- Formulation: Depending on the intended use, NR can be formulated into different products, such as dietary supplements. Formulation involves blending NR with other excipients or ingredients to create the final product.

- Safety Testing: Before NR products can be marketed for human consumption, safety testing is typically conducted to assess potential side effects and toxicity.

It’s important to note that the specific methods and materials used in Nicotinamide Riboside (NR) production may vary depending on the manufacturer and intended application. Additionally, research in the field of NR is ongoing, and new methods and discoveries may continue to emerge. Always consult the latest scientific literature and regulatory guidelines for the most up-to-date information on Nicotinamide Riboside.