Producing high-quality Spirulina tablets involves several key steps to ensure purity, potency, and safety. Spirulina is a type of blue-green algae rich in nutrients like protein, vitamins, and minerals, making it a popular dietary supplement. Here’s an overview of the process and factors influencing the quality and production of Spirulina tablets:

Sourcing of Spirulina: Quality starts with the source. Spirulina should be sourced from reputable suppliers who follow strict quality control measures to prevent contamination and ensure purity. Ideally, Spirulina should be cultivated in controlled environments like ponds or tanks free from pollutants and heavy metals.

Cultivation: Spirulina is typically cultivated in freshwater ponds or tanks under controlled conditions. Factors such as water quality, temperature, pH levels, and sunlight exposure play crucial roles in Spirulina growth and quality. Organic cultivation methods may also be preferred by some consumers.

Harvesting: Spirulina is harvested once it reaches peak biomass concentration, usually within 3-4 weeks of cultivation. Harvesting methods should minimize contamination and maintain the integrity of the algae.

Processing: After harvesting, Spirulina is typically filtered to remove excess water and then dried to form a concentrate. Low-temperature drying methods are preferred to preserve nutrient content. The dried Spirulina is then ground into a fine powder.

Quality Control: Quality control checks are essential at every stage of production to ensure purity, potency, and safety. This includes testing for heavy metals, pesticides, microbial contamination, and other contaminants. Certifications from regulatory bodies like the FDA or third-party organizations may be obtained to verify quality standards.

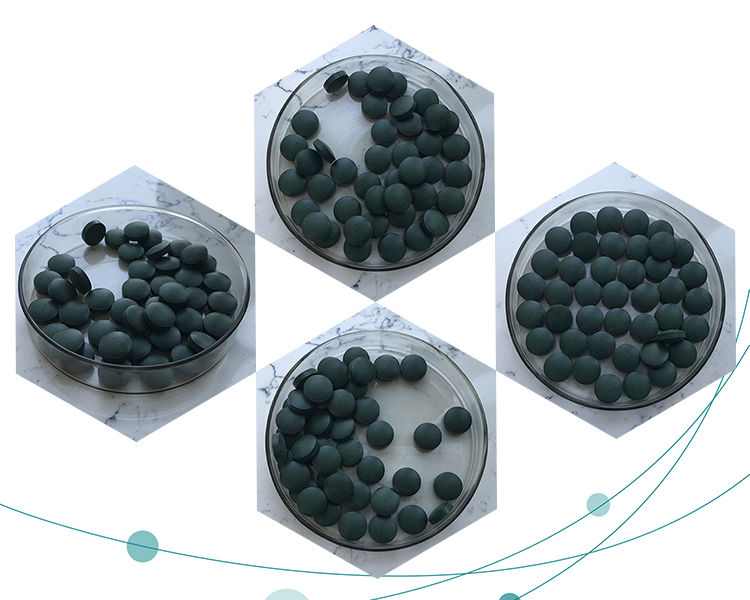

Tablet Formulation: The Spirulina powder is mixed with excipients (binders, disintegrants, lubricants) to facilitate tablet formation. Care should be taken to use natural and safe excipients that do not compromise the quality or purity of the Spirulina.

Tablet Compression: The Spirulina mixture is compressed into tablet form using specialized equipment. Proper compression ensures uniformity of dosage and tablet integrity.

Packaging: Finished Spirulina tablets are then packaged in containers designed to protect them from moisture, light, and air, which can degrade the product over time. Proper labeling should include information on ingredients, dosage, expiration date, and any certifications or quality assurances.

Storage and Distribution: Spirulina tablets should be stored in cool, dry conditions away from direct sunlight to maintain their quality and potency. Proper handling during distribution helps prevent damage and contamination.

Regulatory Compliance: Manufacturers must adhere to regulatory guidelines and standards set by local health authorities to ensure product safety and legality.

By following these steps and maintaining rigorous quality control measures, producers can create high-quality Spirulina tablets that meet consumer expectations for purity, potency, and safety. Additionally, transparency in sourcing and production practices can build trust with consumers seeking reliable dietary supplements.