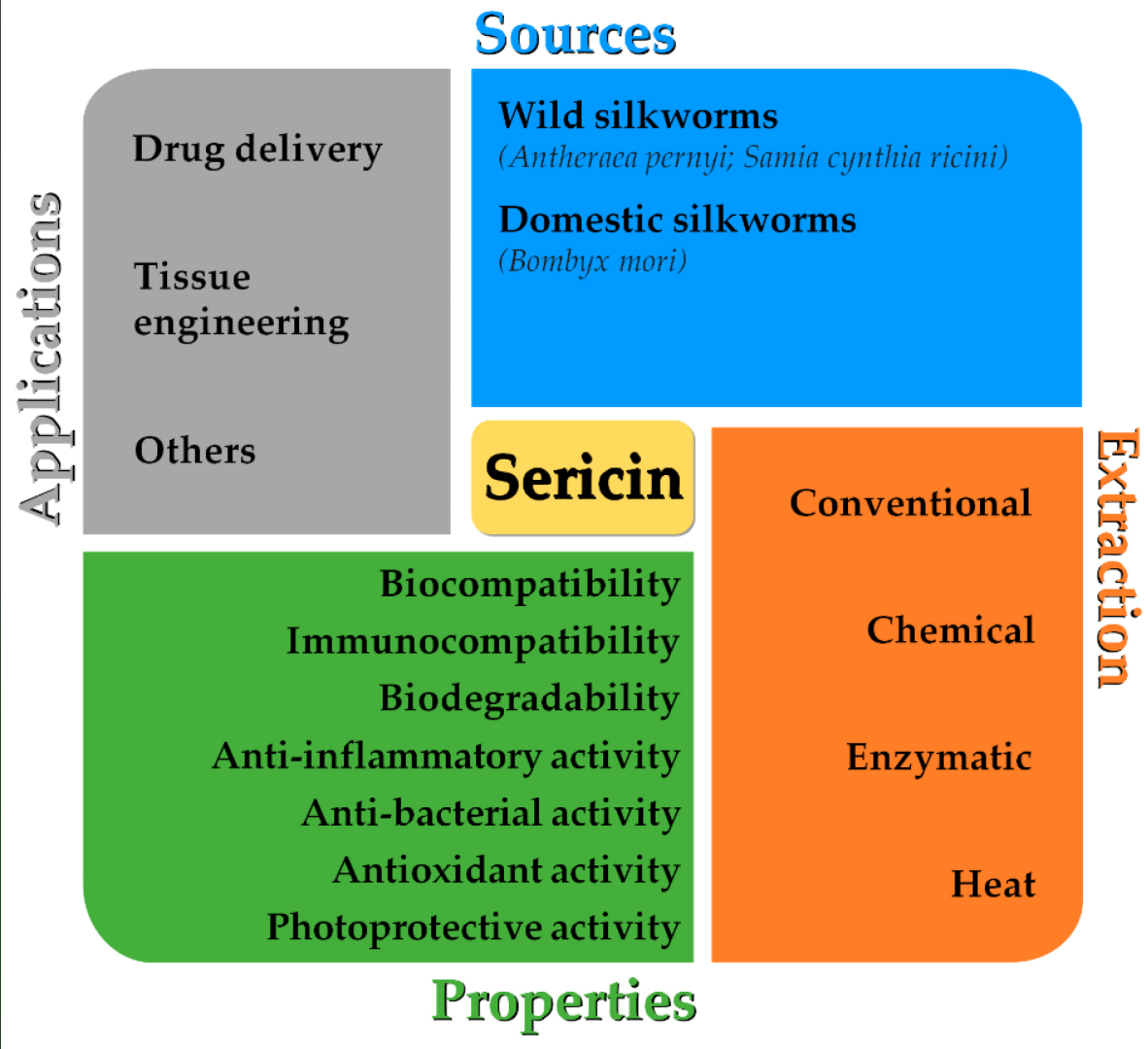

Extraction of sericin, a protein derived from silkworm cocoons (primarily Bombyx mori), involves processes that separate it from silk fibroin. Below are common methods used for sericin extraction:

1. Hot Water Extraction

Process:

- The silk cocoons are boiled in water, often with adjustments to pH and temperature. This method leverages the solubility of sericin in water at high temperatures.

Parameters:

- Temperature: 100°C

- Time: 30–90 minutes

- pH: Neutral or adjusted with acidic or alkaline agents.

Advantages:

- Simple and cost-effective.

- Retains bioactivity of sericin to some extent.

Limitations:

- Low yield compared to advanced methods.

- Risk of partial degradation.

2. Alkaline or Acid Extraction

Process:

- Alkaline (e.g., sodium carbonate or sodium hydroxide) or acidic (e.g., citric acid) solutions are used to enhance the solubility of sericin in water.

Parameters:

- Alkaline or acidic pH (pH 10–12 for alkaline, pH 3–5 for acid).

- Temperature: 80–120°C.

- Time: 30–60 minutes.

Advantages:

- Higher yield compared to hot water extraction.

- Allows customization based on sericin’s intended application.

Limitations:

- Possibility of protein denaturation.

- Risk of contamination by chemicals.

3. Enzymatic Extraction

Process:

- Proteolytic enzymes (e.g., papain, trypsin) are used to selectively break down the sericin-fibroin bonds.

Advantages:

- Gentle extraction, preserving sericin’s bioactive properties.

- Suitable for cosmetic and pharmaceutical applications.

Limitations:

- Relatively expensive.

- Requires precise control of enzymatic activity.

4. Autoclave Extraction

Process:

- High-pressure steam is used in an autoclave to extract sericin.

Parameters:

- Temperature: 120–140°C.

- Pressure: 1–3 bar.

- Time: 15–30 minutes.

Advantages:

- Effective and quick.

- Minimal use of chemicals.

Limitations:

- High energy consumption.

- Risk of thermal degradation.

5. Microwave-Assisted Extraction (MAE)

Process:

- Microwaves are used to heat water or a solvent medium, aiding sericin release from silk.

Parameters:

- Power: 200–800 W.

- Time: 5–20 minutes.

Advantages:

- Fast and energy-efficient.

- Retains more bioactivity compared to conventional methods.

Limitations:

- Equipment cost.

- Limited scalability.

6. Ultrasonic Extraction

Process:

Ultrasonic waves disrupt the silk structure, releasing sericin into the surrounding solution.

Parameters:

- Frequency: 20–40 kHz.

- Time: 10–30 minutes.

Advantages:

- High efficiency.

- Retains bioactive components well.

Limitations:

- Specialized equipment is needed.

7. Electrochemical Extraction

Process:

- Electrolysis in an aqueous medium is used to solubilize sericin.

Advantages:

- Environmentally friendly.

- Minimal degradation of sericin.

Limitations:

- Requires precise control of electrochemical parameters.

- Not widely adopted.

Final Steps After Extraction

- Filtration: Removes insoluble fibroin and debris.

- Concentration: The sericin solution may be concentrated using vacuum evaporation or lyophilization.

- Purification: Dialysis or chromatography can be employed for applications requiring high purity.

- Drying: Freeze-drying or spray-drying converts sericin into a powder form.

The method chosen depends on the intended use of sericin, such as in cosmetics, pharmaceuticals, or textiles.