Aerogel is unique materials known for their extremely low density, high porosity, and exceptional thermal insulating properties. The materials and methods used to produce aerogels can vary based on the type of aerogel (e.g., silica aerogels, carbon aerogels, polymer aerogels). Here, I’ll provide a general overview of the materials and methods commonly employed in aerogel production:

Materials of Aerogel:

1.Base Material:

Silica Aerogels: Typically derived from silicon compounds like tetraethyl orthosilicate (TEOS) or sodium silicate.

Polymer Aerogels: Polymers such as polyurethane, polyimide, or other organic polymers.

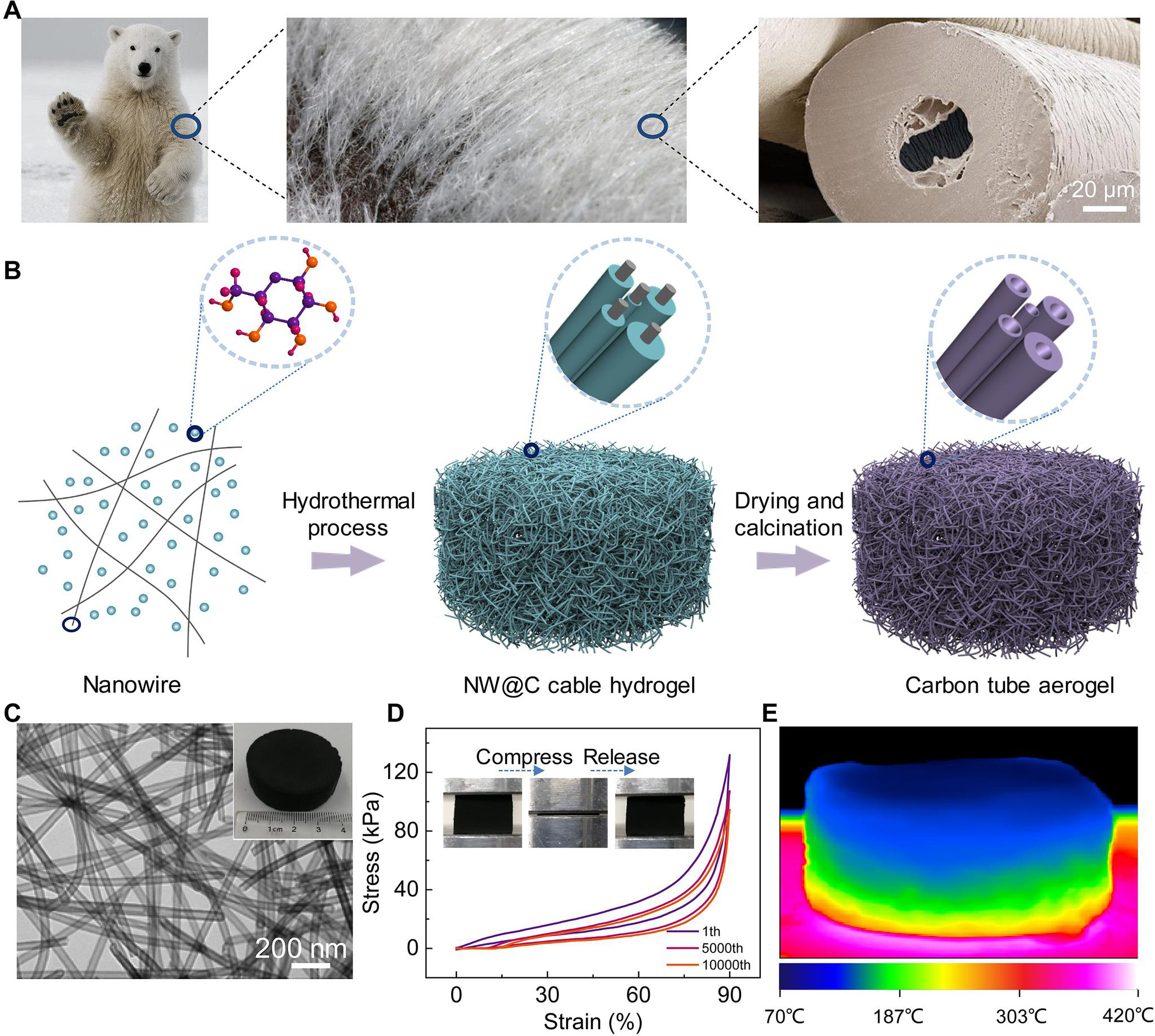

Carbon Aerogels: Derived from organic gels containing carbon-based precursors like resorcinol and formaldehyde.

2.Solvent:

Common solvents include alcohol (e.g., ethanol or isopropanol) for silica aerogel and water for polymer aerogels.

3.Crosslinking Agents:

Used to strengthen the gel structure. For silica aerogels, ammonia is often used as a catalyst.

4.Drying Agents:

Supercritical drying is a crucial step in aerogel production. Common drying agents include carbon dioxide for supercritical drying.

Methods of Aerogel:

1.Gelation:

The process begins with the formation of a gel, achieved through the polymerization or crosslinking of the base material. This creates a three-dimensional network structure with a high surface area.

2.Solvent Exchange:

The gel is then soaked or immersed in a solvent to replace the original liquid with a solvent that can be easily removed in subsequent steps.

3.Supercritical Drying:

The gel is subjected to supercritical drying, where the solvent is replaced with a supercritical fluid (usually supercritical carbon dioxide) to avoid collapse of the gel structure during drying. This step is critical for preserving the aerogel’s low-density and high-porosity properties.

4.Surface Modification (Optional):

Surface modification can be performed to enhance specific properties of the aerogel, such as hydrophobic or hydrophilic characteristics.

5.Pyrolysis (for Carbon Aerogels):

In the case of carbon aerogels, pyrolysis is often performed to convert the organic gel into a carbon-based structure.

6.Characterization:

The final aerogel is characterized using various techniques like scanning electron microscopy (SEM), BET (Brunauer-Emmett-Teller) analysis for surface area measurement, and thermal conductivity measurements.

It’s important to note that the specific details of materials and methods can vary depending on the type of aerogel being produced and the desired properties. Researchers continuously explore new formulations and techniques to improve aerogel properties for various applications, including insulation, catalysis, and sorption.