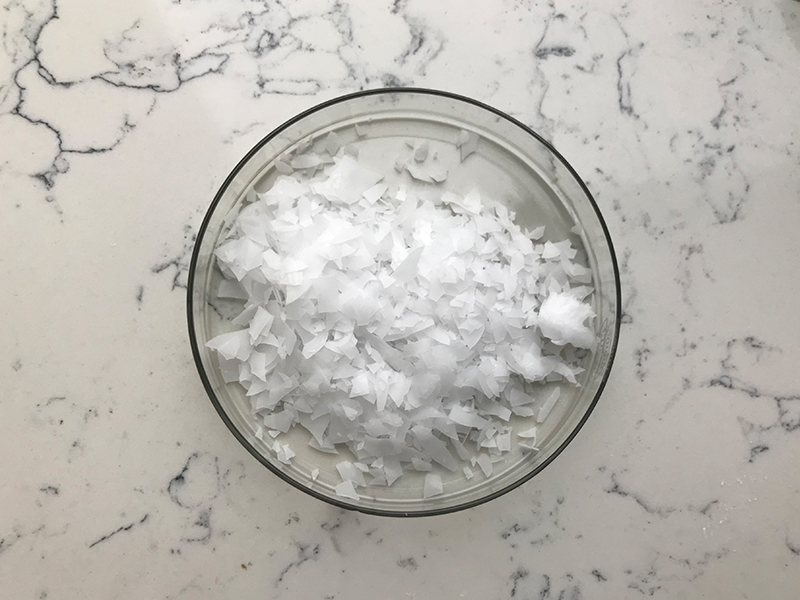

Ceteareth is a mixture of fatty alcohol (cetyl and stearyl alcohol) and ethylene oxide, and it is commonly used in the formulation of cosmetics and personal care products as an emulsifying agent, surfactant, and thickener. It helps to stabilize and emulsify oil and water-based ingredients in various skincare and hair care products. Here are the general materials and methods used in the production of Ceteareth:

Materials of Ceteareth:

1.Cetyl Alcohol: Derived from natural sources like coconut or synthetic sources.

2.Stearyl Alcohol: Typically derived from coconut or palm oil or produced synthetically.

3.Ethylene Oxide (EO): A colorless gas used to ethoxylate the fatty alcohols.

Methods of Ceteareth:

The production of Ceteareth involves the ethoxylation of cetyl alcohol and stearyl alcohol. Ethoxylation is a chemical reaction that involves the addition of ethylene oxide (EO) molecules to the fatty alcohols. This process results in the formation of a polyethylene glycol ether of cetyl and stearyl alcohol, creating Ceteareth with varying ethylene oxide chain lengths.

Here is a simplified version of the process:

1.Weighing and Mixing: Cetyl alcohol and stearyl alcohol are weighed in the appropriate proportions. The exact ratio may vary depending on the desired properties of the final product.

2.Ethoxylation: The fatty alcohols are then subjected to ethoxylation. Ethylene oxide is added to the mixture in the presence of a catalyst, usually an alkaline material like potassium hydroxide. This reaction forms the Ceteareth compound.

3.Neutralization: After ethoxylation, the product is neutralized to remove any remaining traces of the catalyst. This step is essential to ensure the final product meets quality standards and is safe for use in cosmetics.

4.Purification: The resulting mixture is often purified to remove impurities and unreacted starting materials, ensuring the final Ceteareth product is of high purity.

5.Quality Control: The final Ceteareth product undergoes quality control tests to ensure it meets the required specifications, including purity, stability, and absence of contaminants.

It’s important to note that specific manufacturing processes may vary among producers, and the above steps are a general overview of the production of Ceteareth. Additionally, manufacturers need to adhere to regulations and guidelines to ensure the safety and efficacy of the final product in cosmetic formulations.

Treatment of Ceteareth

Ceteareth is a mixture of fatty alcohols consisting predominantly of cetyl and stearyl alcohols that have been reacted with ethylene oxide. It is commonly used in cosmetics and personal care products as an emulsifying agent, surfactant, and thickener. Ceteareth helps stabilize oil-in-water emulsions and improves the texture and feel of cosmetic products.

The treatment of Ceteareth generally refers to its incorporation into formulations during the manufacturing process of cosmetic and personal care products. Here are some common considerations for handling Ceteareth:

1.Emulsification: Ceteareth is often used to create stable emulsions in creams and lotions. To utilize its emulsifying properties effectively, it is mixed with oils and water-based ingredients in specific ratios.

2.Temperature Control: The handling temperature during the manufacturing process is important. Elevated temperatures may be required to ensure proper incorporation and homogeneity of Ceteareth into the formulation. However, excessive heat should be avoided to prevent degradation.

3.pH Consideration: Ceteareth is generally stable over a wide range of pH levels. However, the specific pH of the formulation may affect its performance. Formulators should be aware of the pH requirements of the final product.

4.Compatibility: Ceteareth is compatible with a variety of other cosmetic ingredients. However, it’s always essential to test compatibility with other components of the formulation to avoid any potential issues such as separation or instability.

5.Quality of Raw Materials: The quality of the Ceteareth used is crucial for the final product’s performance. Manufacturers should source high-quality raw materials and ensure they meet the required standards.

6.Regulatory Compliance: Formulations containing Ceteareth should comply with relevant regulations and guidelines in the cosmetic industry. Different regions may have specific requirements regarding the use and concentration of certain ingredients.

7.Storage: Proper storage conditions are essential to maintain the stability of Ceteareth. It should be stored in a cool, dry place, away from direct sunlight, and protected from moisture.

It’s important to note that specific guidelines and considerations may vary depending on the type of cosmetic or personal care product being formulated. Formulators typically follow industry best practices and guidelines provided by regulatory authorities to ensure the safety and efficacy of the final products.