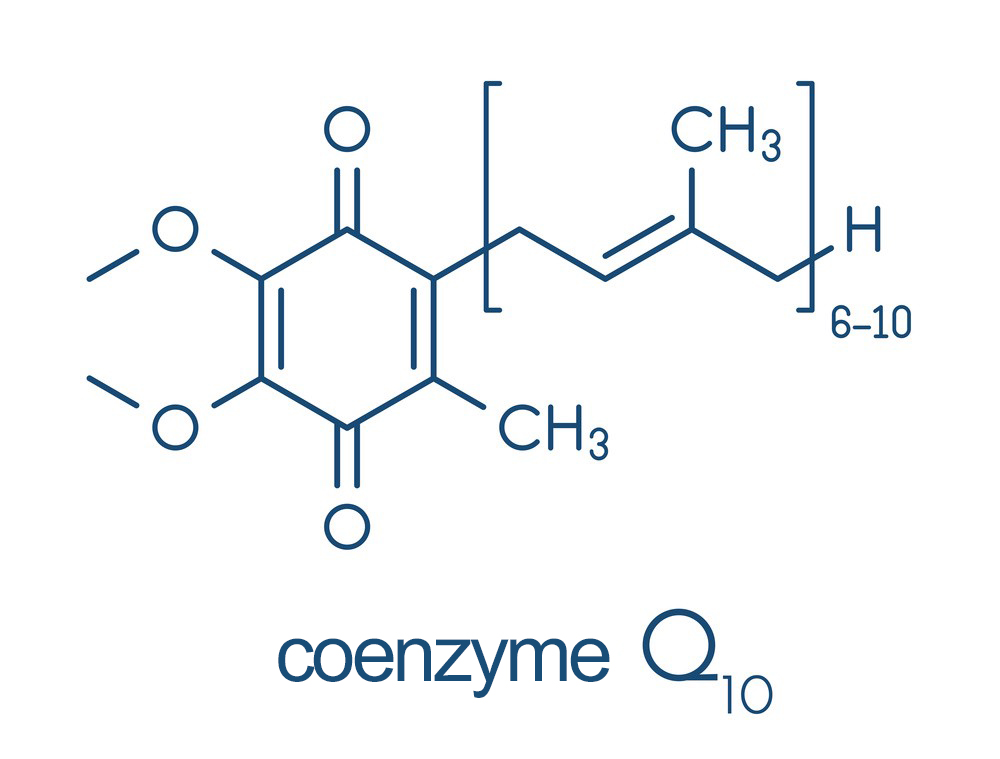

Coenzyme Q10 (CoQ10), also known as ubiquinone, is a naturally occurring compound found in the cells of the human body. It plays a crucial role in energy production within the mitochondria and also functions as an antioxidant. Coenzyme Q10 supplements are often taken for various health benefits. Below are the materials and methods typically associated with Coenzyme Q10 production, extraction, and analysis:

Materials of Coenzyme Q10:

1.Source Organisms: Coenzyme Q10 can be extracted from various natural sources, including bacteria, yeast, plants, and animals. Common sources include soybean oil, yeast fermentation, and bacterial synthesis.

2.Solvents: Organic solvents like hexane, ethanol, or isopropanol are commonly used for Coenzyme Q10 extraction and purification.

3.Laboratory Equipment: This includes centrifuges, rotary evaporators, chromatography columns, and various analytical instruments for characterization.

Methods of Coenzyme Q10:

1.Extraction:

- Coenzyme Q10 can be extracted from the chosen source organism. For example, it can be extracted from soybean oil using a solvent like hexane.

- The extracted material is then purified to remove impurities and unwanted compounds.

2.Fermentation (if applicable):

- In the case of yeast or bacterial production, Coenzyme Q10 can be synthesized through fermentation processes.

- The fermentation process is carefully controlled to optimize Coenzyme Q10 production.

3.Chromatography:

- Chromatographic techniques such as high-performance liquid chromatography (HPLC) are commonly used to separate and purify Coenzyme Q10 from other compounds.

- HPLC can be performed with a suitable column and mobile phase to isolate Coenzyme Q10 based on its chemical properties.

4.Analysis:

- The purity and quality of Coenzyme Q10 are assessed using analytical techniques like UV-Vis spectroscopy, mass spectrometry, and nuclear magnetic resonance (NMR) spectroscopy.

- Quantification of Coenzyme Q10 is often done through calibration curves using known standards.

5.Formulation:

- Coenzyme Q10 supplements can be formulated in various ways, such as softgels, capsules, or tablets.

- Excipients and additives may be used to improve stability, bioavailability, and ease of consumption.

6.Quality Control:

- Coenzyme Q10 products undergo quality control testing to ensure they meet specific purity and potency standards.

- Batch-to-batch testing is crucial to maintain product consistency.

7.Dosage Formulation:

- The final Coenzyme Q10 product is formulated into specific dosages suitable for consumer use.

- The dosage may vary depending on the intended purpose, such as for general health or as part of a treatment plan for specific medical conditions.

It’s important to note that the specific materials and methods used for Coenzyme Q10 production may vary depending on the manufacturer and the intended application of the Coenzyme Q10 product. Additionally, safety and regulatory compliance are critical considerations throughout the production process to ensure the quality and safety of Coenzyme Q10 supplements.