The materials and methods for producing fish oil capsules typically involve several steps, including sourcing raw materials, extraction, purification, encapsulation, and packaging. Here’s a generalized outline of the process:

Materials of Fish Oil Capsules:

Fish Oil: The primary ingredient is fish oil, typically sourced from fatty fish such as salmon, mackerel, sardines, or anchovies. These fish are rich in omega-3 fatty acids, specifically EPA (eicosapentaenoic acid) and DHA (docosahexaenoic acid), which are the active components.

Capsule Shell: Capsules are usually made from gelatin or vegetarian alternatives like cellulose. Gelatin capsules are commonly used due to their stability and compatibility with various fill materials.

Antioxidants/Stabilizers: To prevent oxidation of the fish oil, antioxidants such as vitamin E (tocopherols) or rosemary extract may be added.

Methods of Fish Oil Capsules:

Extraction: Fish oil is extracted from the fish tissue using various methods like cold pressing or molecular distillation. Cold pressing is a mechanical method that involves pressing the fish to release the oil. Molecular distillation is a more advanced process that separates the oil from contaminants and impurities like heavy metals and PCBs (polychlorinated biphenyls).

Purification: The extracted oil undergoes purification to remove impurities, such as heavy metals, PCBs, dioxins, and other contaminants. This process may involve methods like molecular distillation, filtration, or chromatography.

Concentration: Fish oil may be concentrated to increase the levels of EPA and DHA. This can be achieved through processes like molecular distillation or solvent extraction.

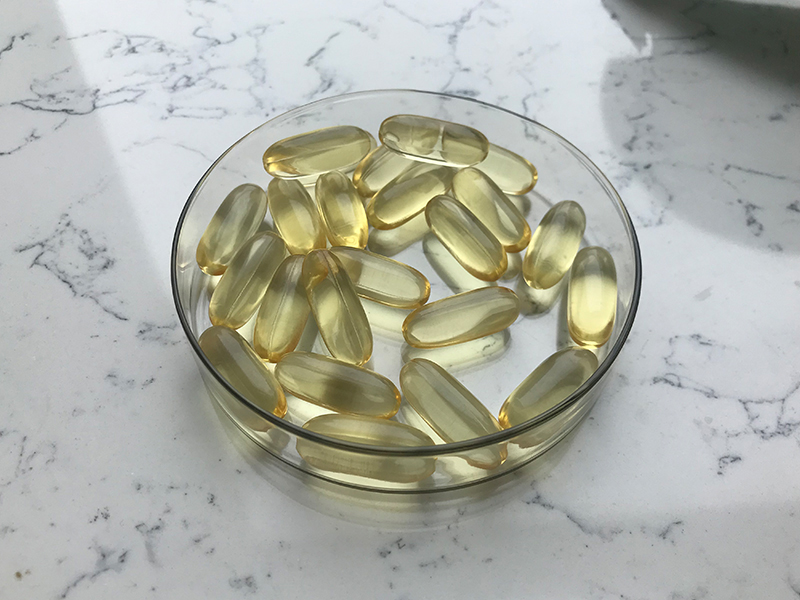

Encapsulation: The purified fish oil is encapsulated into softgel or hard gel capsules. This is typically done using encapsulation machines, which fill the pre-formed capsule shells with the fish oil.

Quality Control: Throughout the manufacturing process, quality control measures are implemented to ensure the capsules meet regulatory standards for purity, potency, and safety. This includes testing for heavy metals, oxidation levels, microbial contamination, and other quality parameters.

Packaging: Once encapsulated, the fish oil capsules are packaged into bottles or blister packs. Packaging materials should be light-resistant and impermeable to oxygen to maintain the stability and freshness of the capsules.

Labeling: The final step involves labeling the product with relevant information, including the ingredients, dosage instructions, expiration date, and any regulatory or quality certifications.

It’s important to note that specific methods may vary depending on the manufacturer and the quality standards they adhere to. Additionally, regulatory requirements in different regions may dictate specific processes to ensure product safety and efficacy.