Liposomal glutathione is a form of glutathione that is encapsulated within liposomes, which are tiny fat-like particles designed to improve the bioavailability and absorption of glutathione in the body. Glutathione itself is a powerful antioxidant that plays a key role in protecting cells from oxidative stress, supporting immune function, and detoxifying the body.

Materials of Liposomal Glutathione:

1.Glutathione (GSH): The primary active ingredient is a tripeptide composed of glutamine, cysteine, and glycine. It acts as an antioxidant.

2.Lipids: The liposomal bilayer is made of phospholipids, typically phosphatidylcholine. These help encapsulate and stabilize the glutathione.

Phosphatidylcholine (PC): Derived from natural sources such as soy or egg lecithin, PC forms the primary structure of liposomes.

3.Cholesterol: Often added to liposome formulations to improve membrane stability and flexibility.

4.Solvents:

Ethanol: Used to dissolve the lipids before forming the liposomes.

Aqueous Buffer Solution: Typically phosphate-buffered saline (PBS), used to hydrate the lipid film and facilitate liposome formation.

5.Cryoprotectants (Optional): Trehalose or mannitol may be added during freeze-drying (lyophilization) to preserve the liposome structure.

Methods of Liposomal Glutathione:

1.Lipid Film Hydration Method (Thin-Film Hydration Method):

Preparation of Lipid Solution: Lipids, such as phosphatidylcholine and cholesterol, are dissolved in an organic solvent (e.g., ethanol or chloroform).

Lipid Film Formation: The lipid solution is evaporated under reduced pressure in a rotary evaporator, creating a thin lipid film on the wall of the flask.

Hydration of the Lipid Film: The lipid film is hydrated with an aqueous glutathione solution. This step is often carried out at a temperature above the lipid transition temperature (e.g., 50-60°C) to facilitate the formation of liposomes.

Sonication or Extrusion: The hydrated lipid suspension is then sonicated or extruded through membranes of defined pore sizes to reduce liposome size and achieve a more uniform distribution.

2.Encapsulation of Glutathione:

During hydration, glutathione is encapsulated within the aqueous core or incorporated into the lipid bilayer of the liposomes, depending on the solubility characteristics of the glutathione.

3.Size Reduction and Homogenization:

After the formation of liposomes, size reduction is performed using techniques like high-pressure homogenization or extrusion. This ensures the liposomes are small and uniform in size, typically in the range of 100-200 nm.

4.Characterization of Liposomal Glutathione:

Particle Size Analysis: Dynamic light scattering (DLS) or nanoparticle tracking analysis (NTA) is used to determine the average particle size and polydispersity index (PDI) of the liposomes.

Zeta Potential Measurement: The surface charge of the liposomes is measured to assess their stability.

Encapsulation Efficiency: The amount of glutathione encapsulated within the liposomes is determined using techniques like UV-Vis spectrophotometry or high-performance liquid chromatography (HPLC).

Stability Testing: Liposomal stability is evaluated over time, often by monitoring particle size, zeta potential, and encapsulation efficiency.

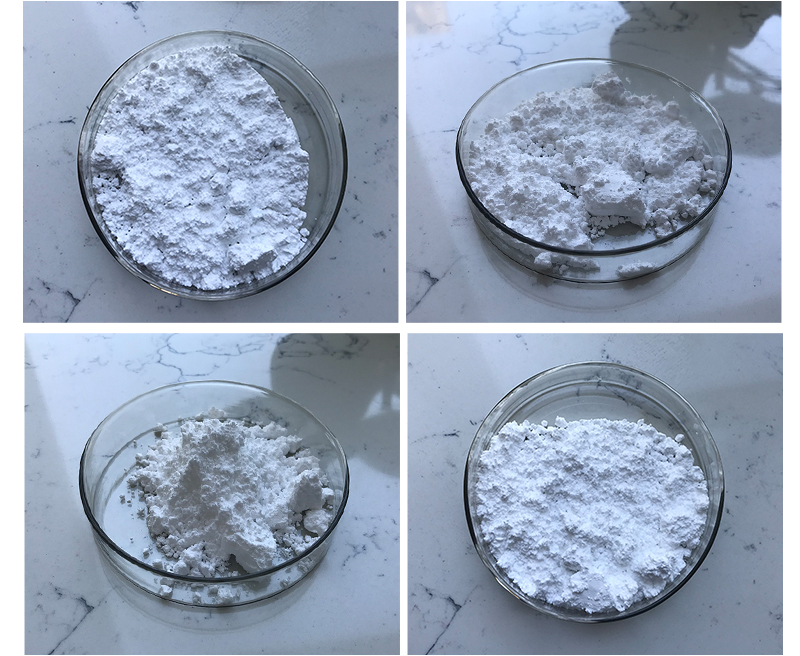

5.Lyophilization (Optional):

To improve the shelf life, liposomal glutathione formulations may be freeze-dried. Cryoprotectants like trehalose are added to preserve the liposomal structure during freezing and drying.

6.In Vitro and In Vivo Testing:

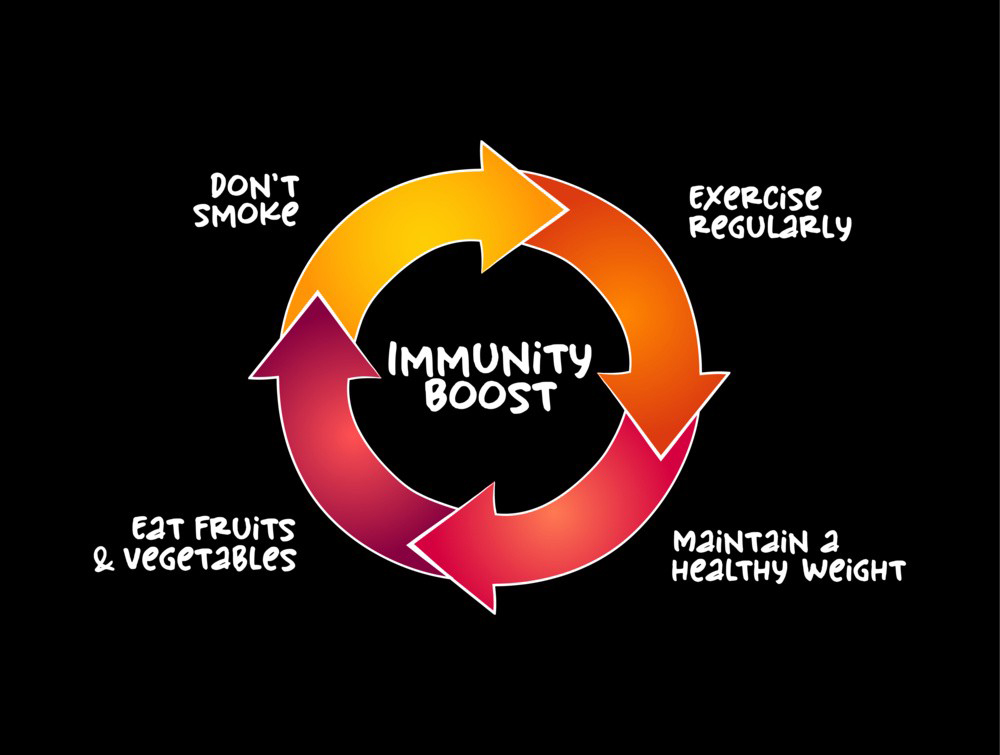

The biological activity of liposomal glutathione is assessed in vitro using antioxidant assays or cell culture models. In vivo, studies may involve evaluating bioavailability, pharmacokinetics, and therapeutic efficacy in animal models or clinical trials.

This method aims to enhance the bioavailability and stability of glutathione by protecting it within liposomal carriers, overcoming the challenge of rapid degradation in the gastrointestinal tract when taken orally.