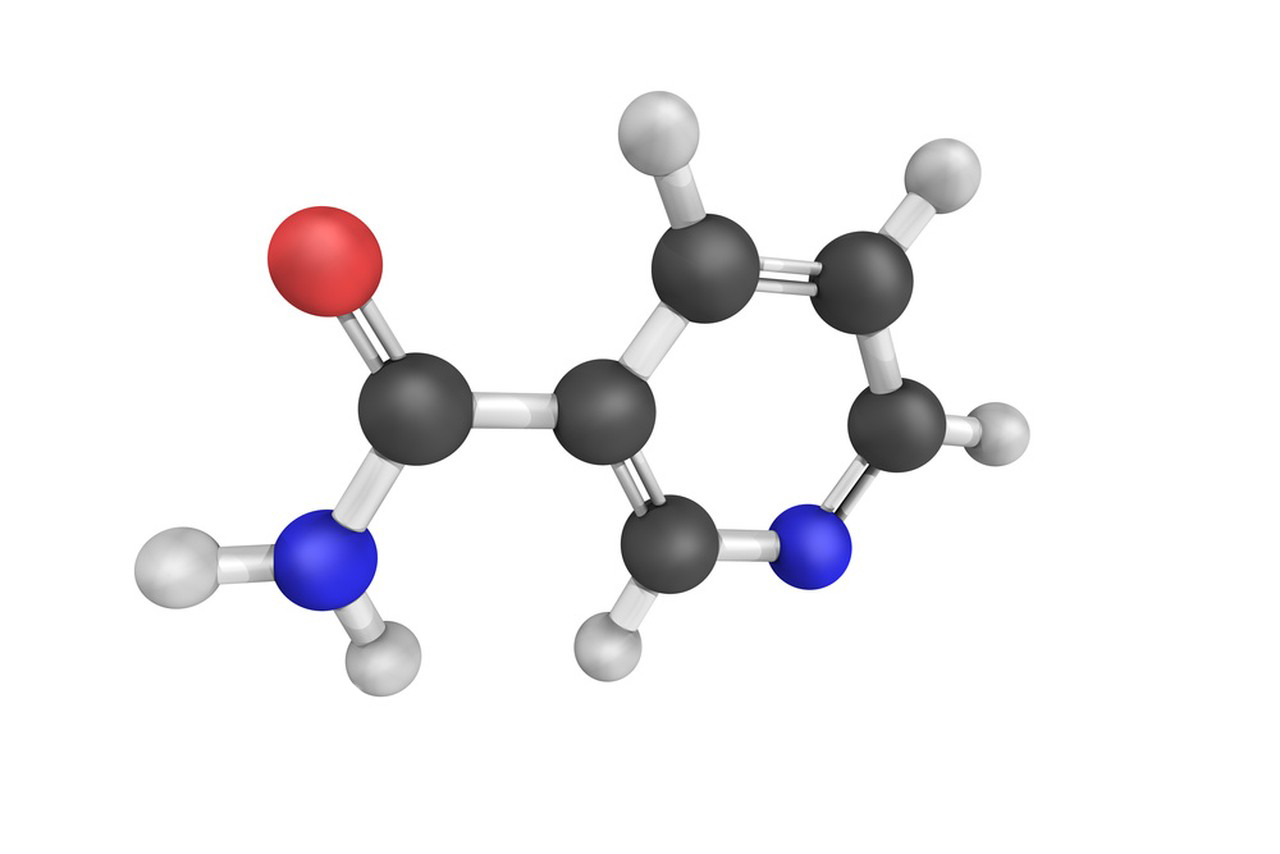

Nicotinamide capsules are a dietary supplement containing nicotinamide, which is a form of vitamin B3, also known as niacinamide. Here’s a general outline of the materials and methods typically used in the production of nicotinamide capsules:

Materials of Nicotinamide Capsules:

1.Nicotinamide powder: The active ingredient, usually sourced from pharmaceutical-grade suppliers.

2.Capsule shells: Typically made from gelatin or vegetarian alternatives like HPMC (Hydroxypropyl Methylcellulose).

3.Excipients: These are inert substances added to the formulation to aid in the manufacturing process or improve stability, flowability, or other properties of the final product. Examples include fillers, binders, lubricants, and disintegrants.

4.Optional additives: Depending on the formulation, additional ingredients such as coloring agents, flavorings, or preservatives may be included.

Methods of Nicotinamide Capsules:

1.Weighing and Mixing:

Nicotinamide powder and excipients are accurately weighed according to the desired dosage and batch size.

These ingredients are then mixed thoroughly to ensure homogeneity.

2.Capsule Filling:

The mixed powder blend is filled into empty capsule shells using capsule filling equipment.

Capsules are typically filled to meet the specified dosage, often under controlled conditions to ensure uniformity.

3.Capsule Sealing:

After filling, the two halves of the capsule shell are joined together, usually by mechanical or manual methods.

4.Quality Control:

Samples from each batch are tested to ensure compliance with regulatory standards regarding potency, purity, and dissolution characteristics.

Various tests may include assays to determine the concentration of nicotinamide, disintegration tests to assess capsule dissolution, and microbiological analysis to ensure product safety.

5.Packaging:

Once quality control checks are completed, the capsules are packaged into appropriate containers, such as bottles or blister packs.

Labels containing essential information such as dosage instructions, batch number, expiry date, and manufacturer details are affixed to the packaging.

6.Storage:

Finished capsules are stored under appropriate conditions to maintain stability and prevent degradation of the active ingredient.

Storage conditions typically include protection from light, moisture, and temperature extremes.

7.Regulatory Compliance:

Manufacturers must adhere to regulatory guidelines set by government agencies such as the FDA (in the United States) or the EMA (in Europe) to ensure product safety and efficacy.

Compliance with Good Manufacturing Practices (GMP) is essential throughout the manufacturing process to maintain quality standards.

These methods may vary slightly depending on the specific formulation and manufacturing processes employed by different pharmaceutical companies. Additionally, it’s crucial for manufacturers to continuously monitor and adjust their processes to ensure consistent quality and compliance with regulatory requirements.