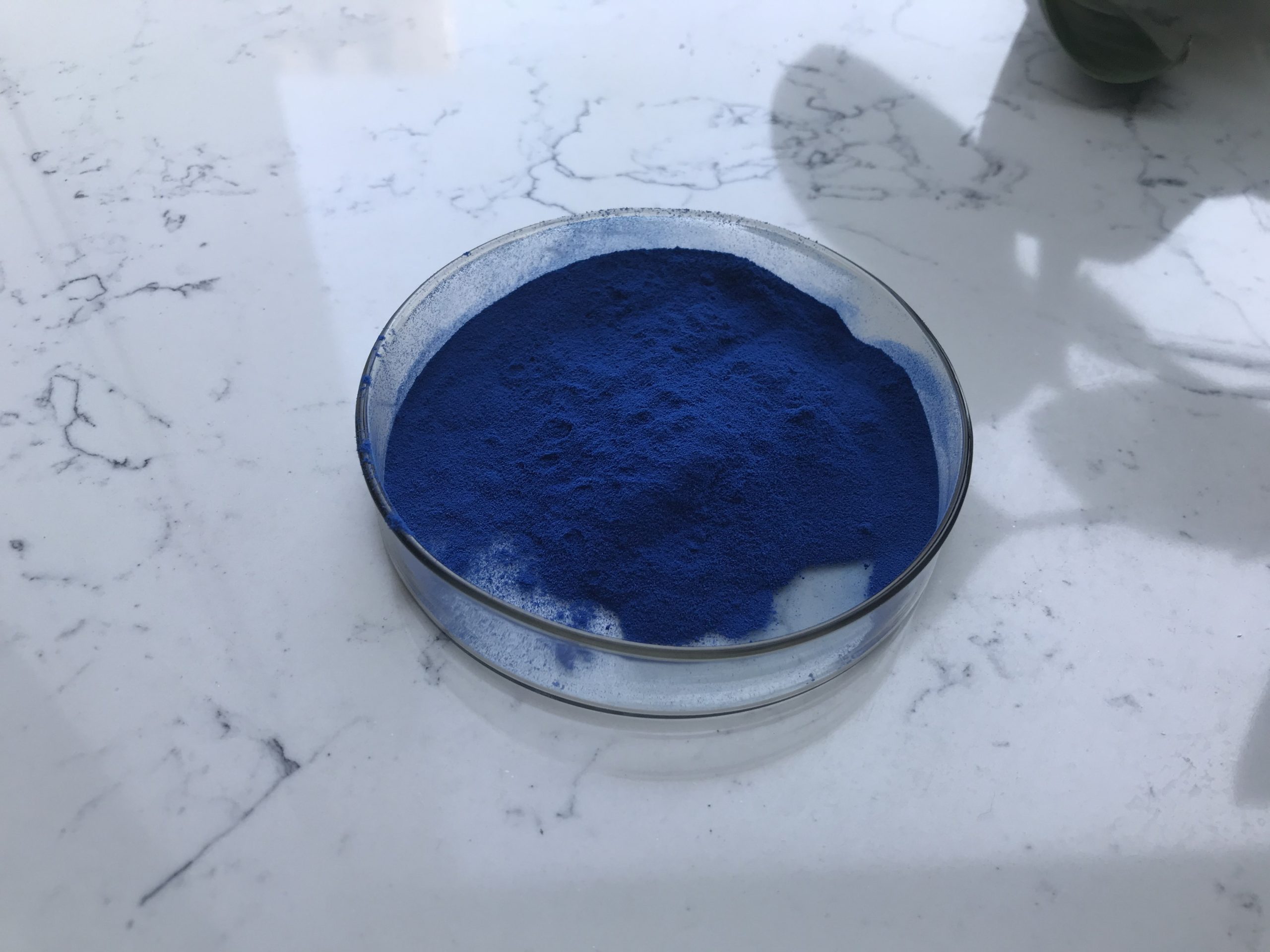

Phycocyanin is a natural blue pigment found in certain types of cyanobacteria and some algae. It is often used in food and cosmetic products as a natural colorant and has potential health benefits due to its antioxidant properties. If you’re looking for information on the materials and methods used to extract and purify phycocyanin, here’s a general outline:

Materials of Phycocyanin:

Cyanobacteria or Algae: These are the primary sources of phycocyanin. Common species include Arthrospira platensis (Spirulina) and Nostoc, but there are many others.

Cultivation Equipment: If you are producing phycocyanin on a larger scale, you’ll need equipment for cultivating the cyanobacteria or algae. This may include bioreactors, photobioreactors, or open ponds.

Harvesting Equipment: Depending on the scale of production, you may use methods such as centrifugation, filtration, or sedimentation to harvest the cyanobacteria or algae.

Cell Disruption Equipment: To release the phycocyanin from the cells, you’ll need equipment like ultrasonic homogenizers or bead mills.

Buffer Solutions: Phycocyanin extraction often involves using buffers, such as phosphate buffers, to stabilize the pigment.

Solvents: Solvents like acetone or ethanol are used for phycocyanin extraction.

Centrifuges: These are used for separating the cellular debris and pigment.

Chromatography Columns: For purification, techniques like gel filtration chromatography or ion-exchange chromatography are commonly used.

UV-Visible Spectrophotometer: To measure the absorbance of phycocyanin and determine its concentration.

Laboratory Glassware and Instruments: Including beakers, pipettes, centrifuge tubes, and other standard lab equipment.

Methods of Phycocyanin:

Cultivation: Cyanobacteria or algae are cultivated under controlled conditions, such as appropriate light, temperature, and nutrient supply.

Harvesting: The cyanobacteria or algae are harvested using the chosen method (e.g., centrifugation or filtration).

Cell Disruption: The harvested cells are disrupted to release the phycocyanin. This can be done through mechanical or chemical means, depending on the equipment and process chosen.

Extraction: Phycocyanin is typically extracted using solvents like acetone or ethanol. The solvent is mixed with the disrupted cells to extract the pigment.

Centrifugation: The mixture is centrifuged to separate the solvent containing phycocyanin from cellular debris.

Purification: Purification can involve various chromatographic methods like gel filtration or ion-exchange chromatography to separate phycocyanin from other pigments and impurities.

Concentration: The purified phycocyanin is often concentrated by removing excess solvent through methods like evaporation.

Characterization: The quality and purity of phycocyanin can be characterized using techniques like UV-Visible spectrophotometry to determine its absorbance and concentration.

Packaging and Storage: The final product is packaged and stored under appropriate conditions to maintain its stability and quality.

It’s important to note that the specific methods and materials used for phycocyanin extraction and purification can vary depending on the source organism and the intended application. Researchers and manufacturers may employ different variations of the above methods to obtain high-quality phycocyanin.