Magnesium Ascorbyl Phosphate (MAP) is a water-soluble, stable derivative of Vitamin C commonly used in cosmetics for its antioxidant and skin-brightening properties. The preparation method typically involves the reaction of ascorbic acid with magnesium salts under controlled conditions. Below is a general outline of the preparation process:

Materials Required

- Ascorbic acid (Vitamin C)

- Magnesium salts (commonly magnesium oxide or magnesium hydroxide)

- Phosphate source (such as phosphoric acid or a phosphate salt)

- Solvent (e.g., water)

- Base or pH adjuster (such as sodium hydroxide or potassium hydroxide)

Preparation Steps

1.Dissolution of Ascorbic Acid:

- Dissolve ascorbic acid in deionized water to form a clear solution. Maintain the temperature at around 25–40°C to prevent degradation of ascorbic acid.

2.Addition of Magnesium Source:

- Gradually add magnesium oxide or magnesium hydroxide to the ascorbic acid solution. Stir well to form magnesium ascorbate.

3.Phosphorylation Reaction:

- Add phosphoric acid or a phosphate salt (e.g., sodium or potassium phosphate) to the reaction mixture. This initiates the phosphorylation process, leading to the formation of magnesium ascorbyl phosphate.

4.pH Adjustment:

- Adjust the pH of the reaction mixture to around 6–8 using a suitable base like sodium hydroxide or potassium hydroxide. Maintaining the pH in this range ensures optimal conditions for the reaction and stability of the product.

5.Reaction Completion:

- Allow the reaction to proceed for several hours under constant stirring at a controlled temperature (typically 40–60°C). Monitor the progress of the reaction using techniques such as High-Performance Liquid Chromatography (HPLC).

6.Purification:

- Filter the reaction mixture to remove any insoluble impurities or unreacted magnesium salts. Optionally, perform further purification using recrystallization or dialysis methods.

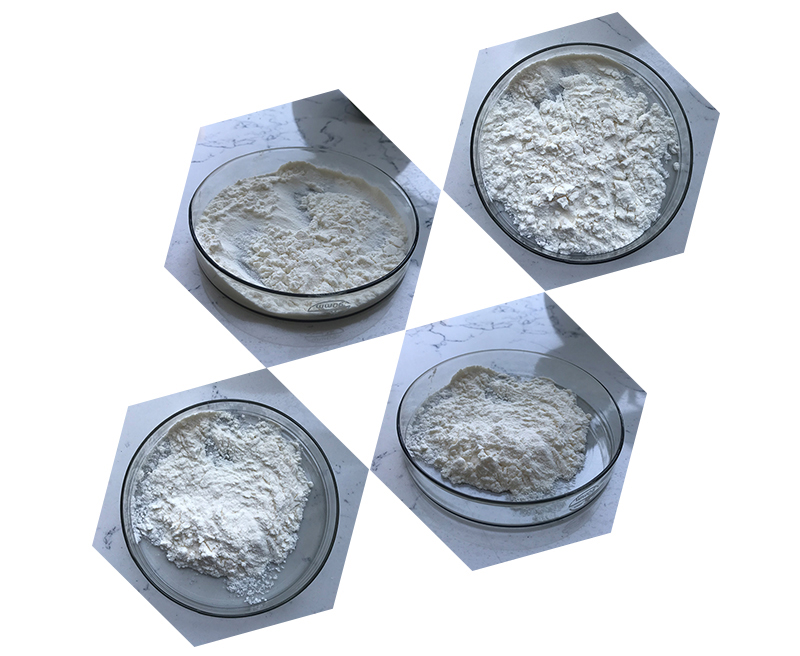

7.Drying:

- Dry the purified product under reduced pressure or in a vacuum oven to obtain Magnesium Ascorbyl Phosphate in a powdered form.

8.Quality Control:

- Test the final product for purity, stability, and pH using standard analytical techniques.

Notes:

- Use inert atmosphere conditions (e.g., nitrogen gas) to minimize oxidation of ascorbic acid during the reaction.

- Handle the product with care as it is sensitive to light and heat.

- Store the final product in an airtight container, preferably under cool and dark conditions, to preserve its stability.

This method can vary slightly depending on specific industrial or laboratory protocols.