Silk fibroin is the main protein component of silk fibers, which are produced by silkworms (Bombyx mori) or other silkworm species. The preparation of silk fibroin involves extracting it from raw silk and processing it into a usable form, typically a solution that can be utilized for various applications, including biomedical, textile, and nanotechnology fields. Below is a general method for preparing silk fibroin:

1. Collection of Raw Silk

Raw silk can be obtained from silkworms or spiders. The silk is generally in the form of cocoon threads.

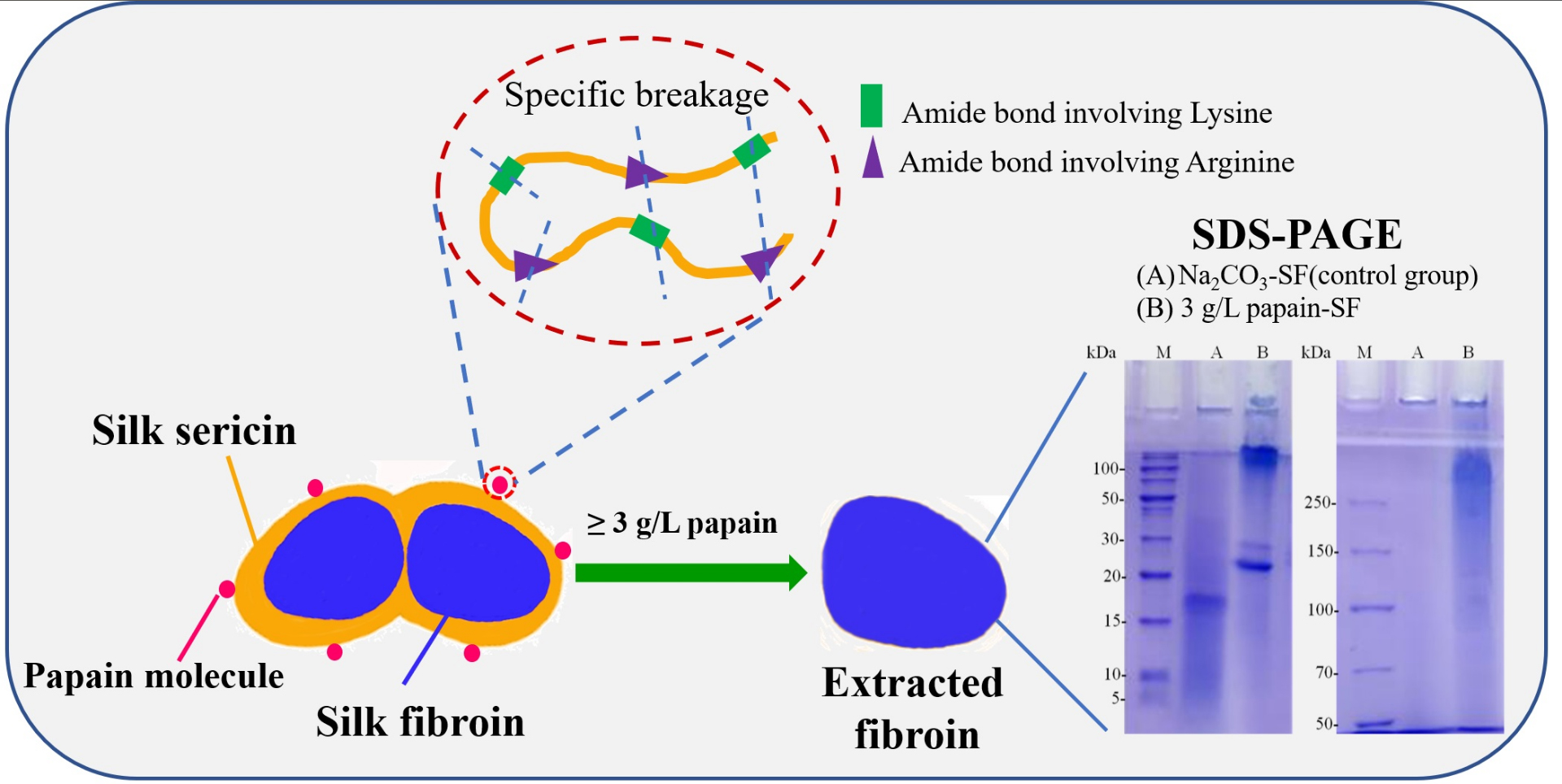

2. Degumming of Silk

Purpose: Remove the sericin protein, which is a sticky protein that holds the fibroin strands together.

Method:

- Soak the raw silk in a hot aqueous solution of sodium carbonate (Na₂CO₃) or sodium bicarbonate (NaHCO₃) at a temperature of 80-100°C.

- The process can take several hours (2-4 hours), and the temperature and pH may be adjusted based on the desired level of sericin removal.

- The raw silk is then rinsed thoroughly with water to remove any residual soap and sericin.

3. Extraction of Silk Fibroin

After degumming, the fibroin is still in solid form, often as fibers or threads.

Dissolution Method:

- The degummed silk is dissolved in a solvent like lithium bromide (LiBr) or calcium chloride (CaCl₂) at elevated temperatures (typically 60-80°C).

- A common concentration for the LiBr solution is around 9-10 M, which helps dissolve the fibroin into a transparent, viscous solution.

- The dissolution process can take several hours to a day, depending on the type of solvent and temperature.

4. Purification of Silk Fibroin

The fibroin solution may contain residual salts, undissolved sericin, and other impurities.

Dialysis is typically used to purify the fibroin solution.

- The solution is dialyzed against distilled water for several days, with frequent changes of water, to remove excess salts (like LiBr) and other small molecules.

- The dialysis can be performed using a dialysis membrane with a molecular weight cut-off (MWCO) of around 3-8 kDa, which allows for the removal of small molecules while retaining the larger fibroin molecules.

5. Concentration and Drying

Once purified, the fibroin solution is typically concentrated by removing excess water, often using freeze-drying or rotary evaporation, depending on the intended final form of the fibroin (solution, film, or scaffold).

For film formation, the fibroin solution can be cast onto a surface (such as a petri dish) and allowed to dry, resulting in a thin fibroin film.

6. Characterization of Silk Fibroin

Once prepared, the silk fibroin can be characterized using several methods to confirm its purity and structural properties:

- UV-Vis Spectroscopy to assess the concentration and quality.

- FTIR (Fourier-Transform Infrared Spectroscopy) to confirm the structural integrity of the protein.

- Circular Dichroism (CD) to analyze the secondary structure of the fibroin (e.g., β-sheet content).

- Gel Electrophoresis to check for the presence of any remaining impurities or fragmented proteins.

Additional Notes:

- Fibroin Assembly: Silk fibroin can self-assemble into different forms, such as films, fibers, scaffolds, or gels, depending on the method of preparation.

- Bioactive Properties: Silk fibroin has been studied for its bioactivity, biocompatibility, and use in tissue engineering, drug delivery, and wound healing.

Would you like more detailed information on any of the steps or potential applications of silk fibroin?