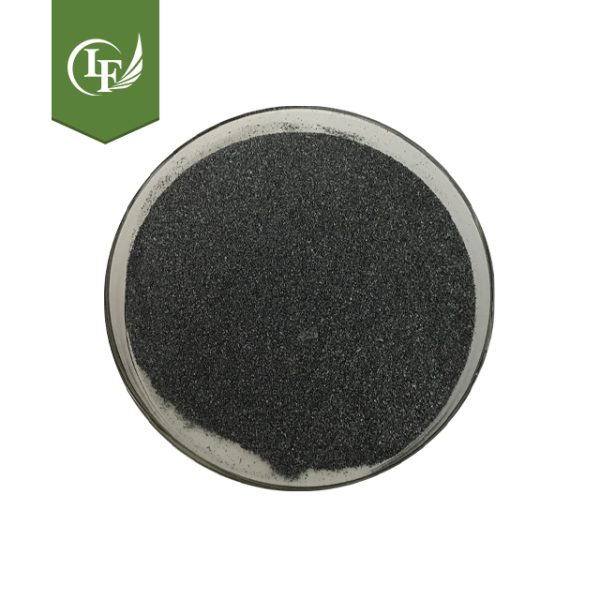

Graphene

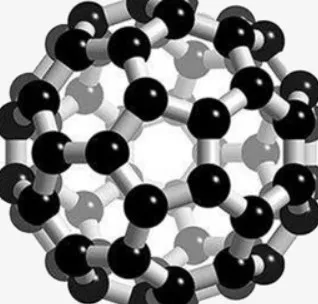

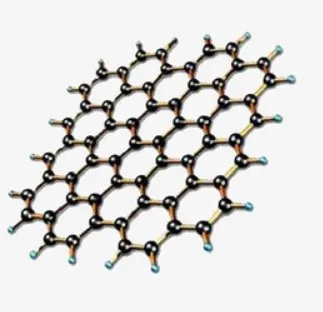

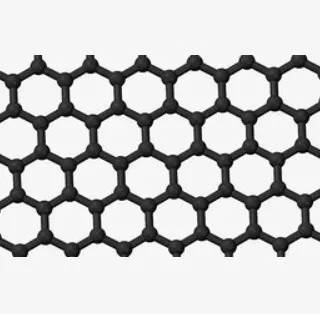

Graphene is a single layer of carbon atoms arranged in a hexagonal lattice, forming a two-dimensional structure. It is often considered a wonder material due to its exceptional properties.

Description

| Product name | Graphene |

| Details | Single Layer Graphene |

| Purity | >99% |

| Thickness | 3-9nm |

Lyphar’s Graphene is practically a one atom thick layer of carbon atoms, densely packed in a hexagonal (honey comb) lattice. The carbon-carbon bond length in graphene is about 0.142 nanometers. It is already known that it has unbelievable strength and conductivity, both of which are a result of its structure.

Lyphar’s Graphene differs from conventional 3D materials in that it is a semi-metal or zero-gap semiconductor. It has a remarkable electron mobility at room temperature and it has been showed it.

| Product | Purity |

| Single-layer graphene | 99% |

| Multilayer graphene | 99% |

| Industrial grade single layer graphene oxide | 99% |

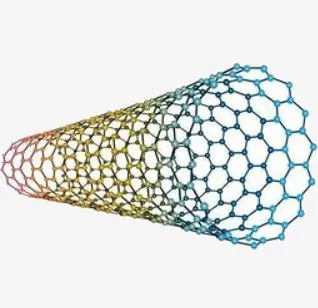

| Graphene nanosheets | 99% |

| Lithium battery |  | Lyphar’s Graphene oxide electrocondution slurry can significantly improve the conductivity ,thermal conductive and process properties, reduce the dosage of conductive agent and adhesive agent, reduce the battery internal resistance, Upgrade the capacity of the battery, high rate discharge capability, cycle life and safety. |

| Plastics industry |  | Lyphar’s Graphene oxide can be directly used in plastics industries. We can supply the graphene dispersion technical guidance in plastics substrate based on the client’s specific requirements. |

| Coatings industry |  | Lyphar’s Graphene oxide can be widely used in coating, printing ink and plastics industries as the outstanding conductivity, thermal conductivity, antistatic and electromagnetic shielding performance. |

| Other industries |  | Lyphar’s Graphene oxide is a kind of carbon nanometer material which integrating a variety of excellent properties. |

| Lower percolation value than that of conductive carbon black. |  | Lyphar’s Graphene oxide can be used as additives in cathode or anode of lithium ion battery to increase the battery’s capacity, cycling life and rate retention. |

| Easy to be processed and dispersed with ultra-thin planar structure. |  |

| Lyphar’s Graphene oxide can be integrated to prepare the thermal conductive composites and thermal radiation coatings. |  | 1-3% addition is suggested for conductive coatings. |