Semaglutide is a medication used to treat type 2 diabetes. It belongs to the class of drugs called glucagon-like peptide-1 (GLP-1) receptor agonists. The process of manufacturing semaglutide involves several steps, including recombinant DNA technology and protein purification. Here is a simplified overview of the semaglutide processing process:

1.Gene Cloning and Expression:

The process begins with the identification and isolation of the gene that codes for the production of GLP-1.

The isolated gene is then cloned using recombinant DNA technology.

The cloned gene is introduced into a host organism, often a strain of Escherichia coli (E. coli) bacteria.

2.Fermentation:

The genetically modified bacteria are cultured in large fermentation tanks.

These bacteria serve as biofactories, producing the GLP-1 analog (semaglutide) during the fermentation process.

3.Harvesting and Cell Disruption:

After fermentation, the bacterial cells containing the produced semaglutide are harvested.

The cells are then disrupted to release the intracellular contents, including the semaglutide protein.

4.Purification:

The crude extract containing semaglutide is subjected to various purification steps to isolate and purify the protein.

Chromatography techniques, such as affinity chromatography and ion exchange chromatography, are commonly used to separate and purify semaglutide from other cellular components.

5.Refolding:

Semaglutide may be produced in an insoluble form during bacterial expression. Refolding is a step where the protein is converted from an inactive, insoluble form into an active, soluble form.

6.Formulation:

The purified and refolded semaglutide is then formulated into the final pharmaceutical product. This may involve the addition of stabilizers, preservatives, and other excipients to ensure the stability and efficacy of the drug.

7.Quality Control:

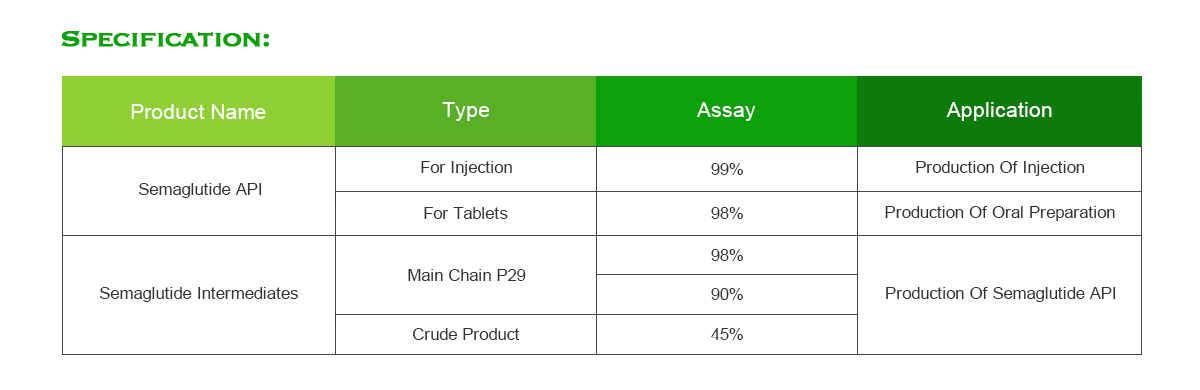

Rigorous quality control measures are implemented at various stages of the manufacturing process to ensure the purity, potency, and safety of semaglutide.

Analytical techniques such as high-performance liquid chromatography (HPLC) and mass spectrometry are commonly used for quality control purposes.

8.Final Product:

The final semaglutide product is then filled into vials or pre-filled pens for distribution and use by patients.

It’s important to note that the specific manufacturing process for semaglutide may vary depending on the pharmaceutical company producing it. The outlined steps provide a general overview of the typical processes involved in producing a recombinant protein like semaglutide. Additionally, advancements in technology and improvements in production processes may lead to variations in the manufacturing of biopharmaceuticals over time.