Synthesis of chitosan oligosaccharides involves the controlled degradation of chitosan, a natural polymer derived from chitin found in the shells of crustaceans like shrimp and crab. Chitosan oligosaccharides have gained interest due to their potential biological and industrial applications, including as dietary supplements, plant growth enhancers, and antimicrobial agents. Here’s a simplified overview of the synthesis process:

1.Chitosan Extraction: Chitosan is typically extracted from crustacean shells using processes that involve demineralization, deproteinization, and deacetylation. This yields chitosan, a linear polysaccharide composed of N-acetylglucosamine (GlcNAc) and glucosamine (GlcN) units.

2.Chitosan Depolymerization: The chitosan polymer is then subjected to controlled depolymerization to break down the long chains into shorter oligosaccharide segments. This can be achieved through various methods, such as enzymatic hydrolysis, acid hydrolysis, or chemical depolymerization.

a. Enzymatic Hydrolysis: Enzymes like chitosanase are used to cleave the glycosidic bonds in chitosan, yielding chitosan oligosaccharides of varying lengths.

b. Acid Hydrolysis: Treatment with acid (e.g., hydrochloric acid) at controlled conditions can break the glycosidic bonds, leading to the formation of chitosan oligosaccharides.

c. Chemical Depolymerization: Specific chemical agents can be used to selectively cleave the glycosidic linkages within chitosan, resulting in the formation of chitosan oligosaccharides.

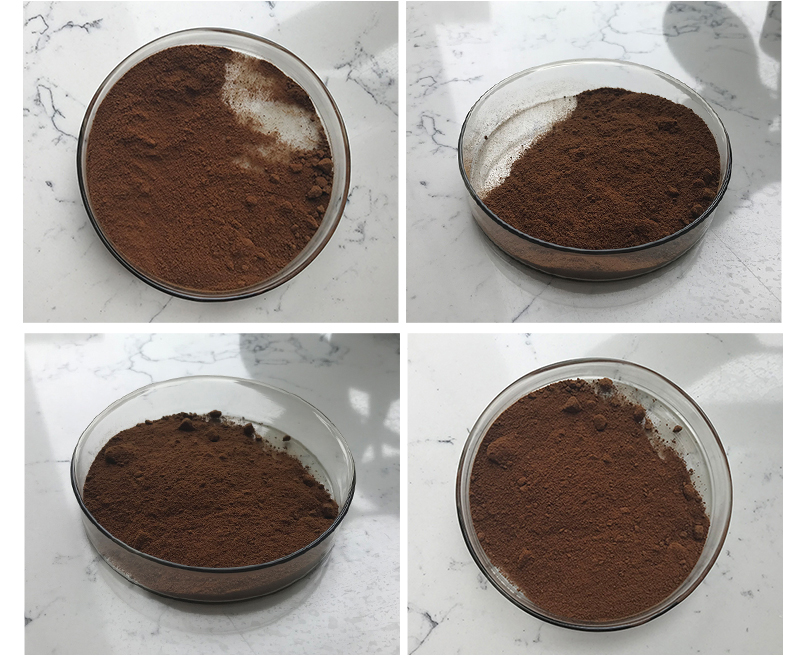

3.Purification: The mixture obtained from depolymerization needs to be purified to isolate the desired chitosan oligosaccharide fractions. Purification methods may include precipitation, filtration, chromatography, and dialysis.

4.Characterization: The synthesized chitosan oligosaccharides should be characterized using various analytical techniques, such as nuclear magnetic resonance (NMR) spectroscopy, size-exclusion chromatography (SEC), and high-performance liquid chromatography (HPLC). This helps determine their molecular weight distribution, degree of polymerization, and other structural properties.

5.Applications: Chitosan oligosaccharides can be utilized in various fields, such as agriculture (as plant growth promoters and elicitors of plant defense mechanisms), medicine (for their potential bioactivity and health benefits), and biotechnology (as encapsulation materials or drug delivery systems).

It’s important to note that the specific synthesis methods and conditions can vary depending on the desired properties of the chitosan oligosaccharides and the intended applications. Additionally, safety considerations and regulations should be followed, especially when considering the use of chitosan oligosaccharides in food and pharmaceutical applications.

The basic element of the Chitosan Oligosaccharide

The basic element of chitosan oligosaccharide is the monomeric unit, which is a simple molecule that repeats to form the larger chitosan oligosaccharide structure. Chitosan itself is a biopolymer derived from chitin, which is a natural polymer found in the shells of crustaceans like shrimp, crabs, and lobsters, as well as in the cell walls of some fungi.

Chitosan oligosaccharide is obtained by enzymatic or chemical degradation of chitosan, breaking down the larger chitosan molecules into smaller oligosaccharide units. These oligosaccharide units consist of a chain of sugar molecules, specifically glucosamine and N-acetylglucosamine.

In summary, the basic element of chitosan oligosaccharide is the monomeric unit composed of glucosamine and N-acetylglucosamine, which are linked together to form the larger chitosan oligosaccharide structure.