Aerogel is unique materials known for their low density, high porosity, and exceptional thermal insulating properties. They are colloidal substances that have a gel-like structure, but the liquid component is replaced with gas. Here’s a comprehensive overview of aerogels, covering their properties, types, applications, and current research trends:

1.Introduction to Aerogel:

Definition: Aerogels are a class of extremely light and porous materials derived from a gel, where the liquid component is replaced with a gas, resulting in a solid with low density.

Composition: Typically composed of a network of interconnected nanoparticles, creating a highly porous structure.

Origins: First synthesized in the 1930s by Samuel Kistler, aerogels have since been developed and studied extensively.

2.Properties of Aerogel:

Low Density: Often referred to as the lightest solid materials; density is usually in the range of 0.001 to 0.5 g/cm³.

High Porosity: Can have porosities exceeding 99%, providing an enormous surface area.

Exceptional Insulation: Remarkable thermal insulating properties make aerogel suitable for various applications.

Transparent: Some aerogels, like silica aerogels, can be highly transparent.

3.Types of Aerogel:

Silica Aerogels: Commonly known and extensively researched, silica aerogels are transparent and have excellent thermal insulating properties.

Polymer Aerogels: Derived from organic polymers, offering flexibility and diverse applications.

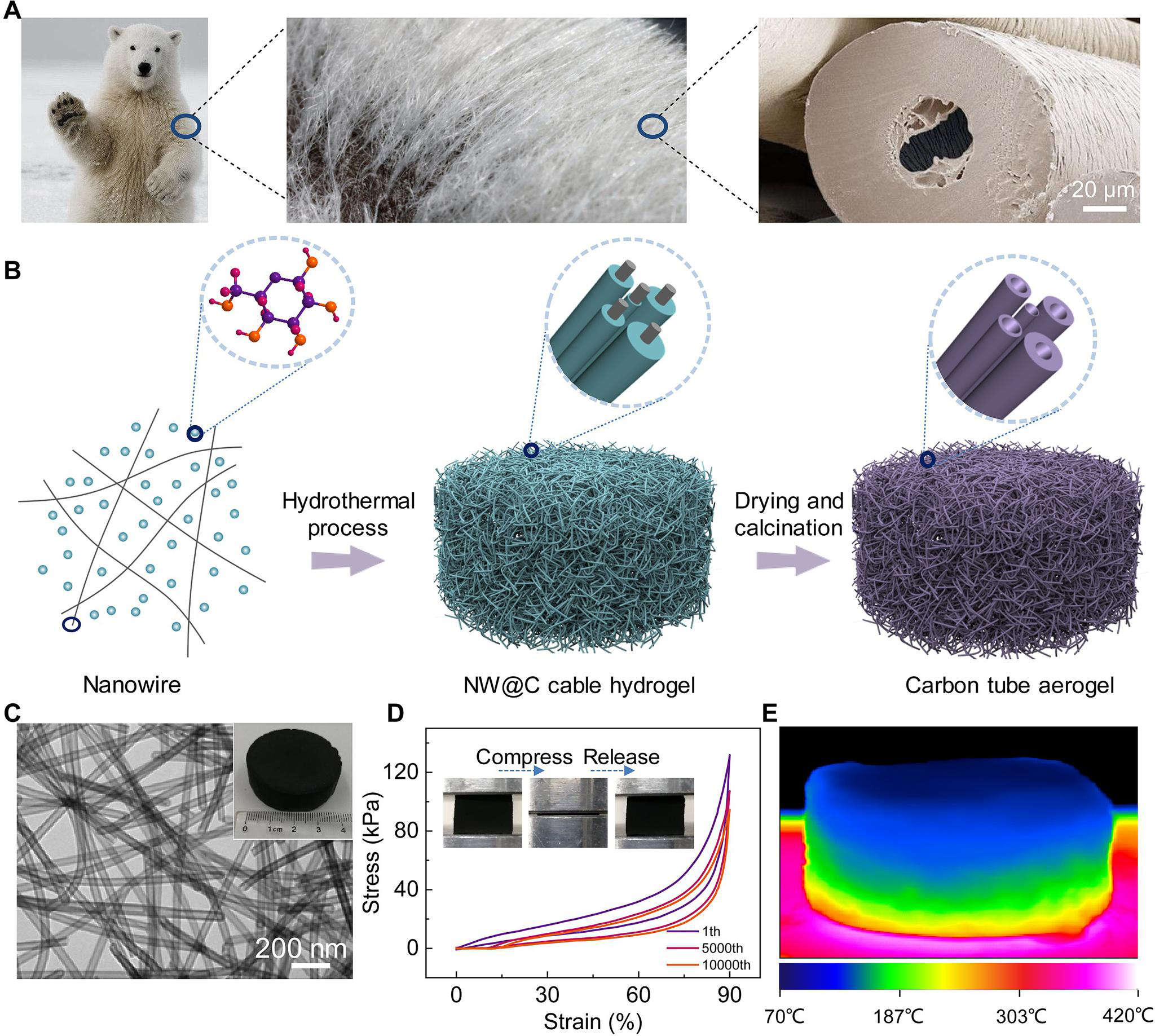

Carbon Aerogels: Made from carbon-based materials, these aerogels exhibit unique electrical conductivity and mechanical strength.

4.Applications:

Insulation: Used in space exploration, construction, and clothing for superior thermal insulation.

Oil Spill Cleanup: Hydrophobic aerogel can selectively absorb oil from water, making them effective in cleaning up oil spills.

Catalysis: Aerogels serve as excellent catalyst supports due to their high surface area.

Electronics: Carbon aerogels find applications in energy storage devices and supercapacitors.

Medical: Potential applications in drug delivery, tissue engineering, and wound healing.

5.Current Research Trends:

Functionalization: Researchers are exploring methods to functionalize aerogels for specific applications, enhancing their properties.

Biodegradable Aerogels: Environmentally friendly aerogels are being developed using biodegradable materials.

Advanced Manufacturing Techniques: Investigating new techniques such as 3D printing for precise and customized aerogel structures.

Nanocomposite Aerogel: Integrating nanoparticles into aerogel matrices for improved performance in various fields.

6.Challenges and Future Prospects:

Cost: The production of aerogels can be expensive, limiting widespread adoption.

Mechanical Strength: Enhancing the mechanical strength of aerogel without compromising their low density is an ongoing challenge.

Scale-Up: Scaling up production methods for practical applications remains a focus of research.

In conclusion, aerogels have captivated the interest of researchers and industries alike due to their exceptional properties and versatile applications. Ongoing research is focused on addressing challenges, expanding applications, and developing more sustainable and cost-effective production methods.