Aerogel is a unique material known for its extremely low density and excellent thermal insulating properties. While it has various advantages, it also comes with some challenges. Here are the pros and cons of aerogel:

Pros of Aerogel:

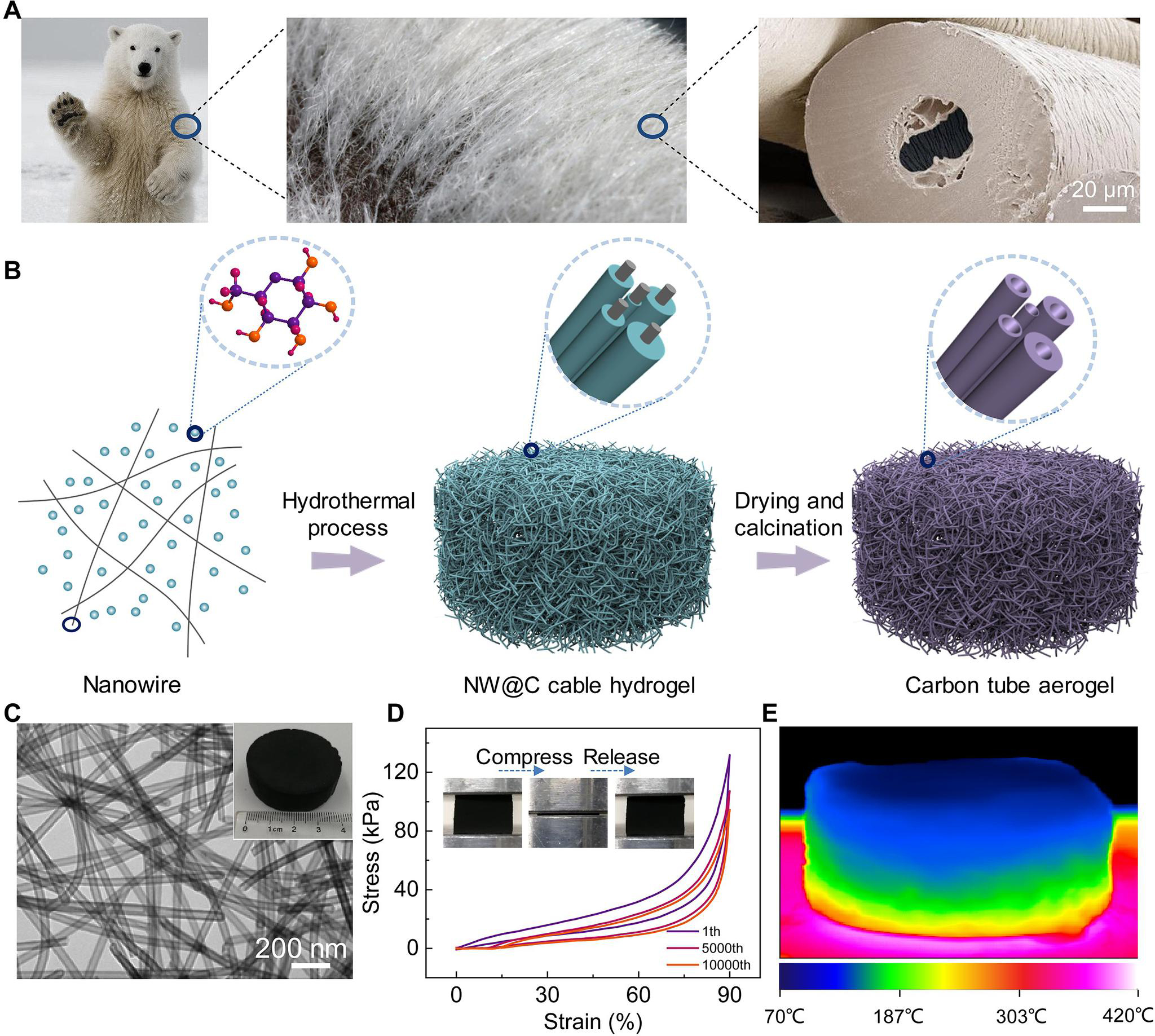

Low Density: Aerogels are incredibly lightweight, with densities as low as 0.001 g/cm³. This makes them one of the lightest solid materials known.

Thermal Insulation: Aerogels have exceptional thermal insulating properties. They are highly effective at preventing heat transfer, making them useful in applications where thermal insulation is critical.

Low Thermal Conductivity: Aerogel have very low thermal conductivity, making them excellent insulators. This property is particularly valuable in applications such as spacecraft insulation and energy-efficient building materials.

Versatility: Aerogels can be made from a variety of materials, including silica, polymer, and carbon. This versatility allows for customization based on specific applications and requirements.

Transparent Varieties: Silica aerogels, in particular, can be produced in a transparent form, allowing for potential applications in optics and window insulation.

Chemical Inertness: Aerogel is generally chemically inert, making them resistant to many chemicals and environmental conditions.

Cons of Aerogel:

Fragility: Aerogels are extremely fragile and can be easily damaged. Handling them requires care, as they can break or crumble with minimal force.

Cost: Producing aerogels can be an expensive process, which limits their widespread use. However, ongoing research and advancements may lead to cost reductions in the future.

Hydrophobicity: Silica aerogels, in particular, are hydrophobic, meaning they repel water. While this can be an advantage in some applications, it can also limit certain uses where water absorption is desired.

Limited Mechanical Strength: Aerogel generally have low mechanical strength. This limits their use in structural applications where strength and durability are crucial.

Complex Manufacturing Process: The production of aerogels involves complex and often time-consuming processes, which can contribute to their higher cost.

Limited Commercial Availability: Despite their unique properties, aerogels are not as readily available in the commercial market compared to more traditional materials. This can be a constraint for widespread adoption in various industries.

In conclusion, aerogel offer remarkable properties such as low density and excellent thermal insulation, but their fragility, cost, and limited mechanical strength may restrict their use in certain applications. Ongoing research and advancements in manufacturing processes may address some of these limitations and expand the range of practical applications for aerogels.